Chapter 2 Ideal Chemical Reactor Design

Process design has to do with specific matters relating to the process itself, in our cases, such as operation conditions, size, configuration, and operation mode of the reactor.

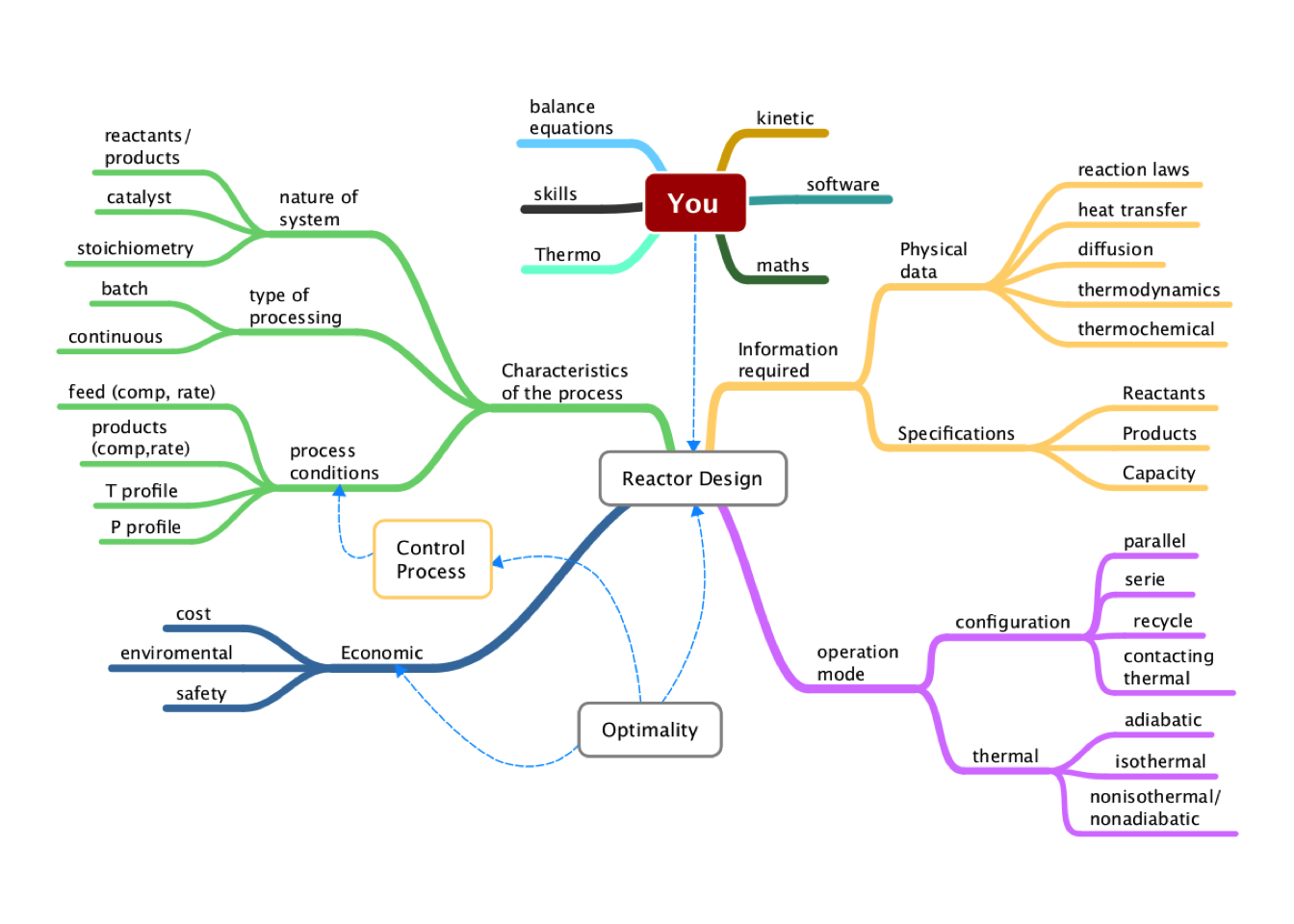

Figure 2.1: Conceptual Map of Chemical Reactor Design

In this course, we will focus on the phenomena taking place in basic reactor types.

The phenomena occurring in a reactor may be broken down into reaction, mass, heat, and momentum transfer. Therefore, reactors’ modeling and design are based on the reaction rate equation, the continuity, energy, and momentum equations. The modeling and design of reactors are based on the equations describing these phenomena: the reaction rate equation and the continuity, energy, and momentum equations (Froment, Bischoff, and De Wilde 2011).

Additionally, we will study two situations (1) the design of a new chemical reactor for a new process, (2) the analysis of the performance of an existing reactor for a current process. In many cases, as chemical engineers, we must consider several items shown in figure 2.1 when starts the design or analysis of a reactor.

2.1 Fundamental Balances

2.1.1 Material Balance

As a chemical engineer, our main modeling tools are the material balance and energy balance. We should remember two aspects: the material balance of a reactor must consider the rate at which species are converted from one chemical form to another and the rate at which energy is transformed by the process.

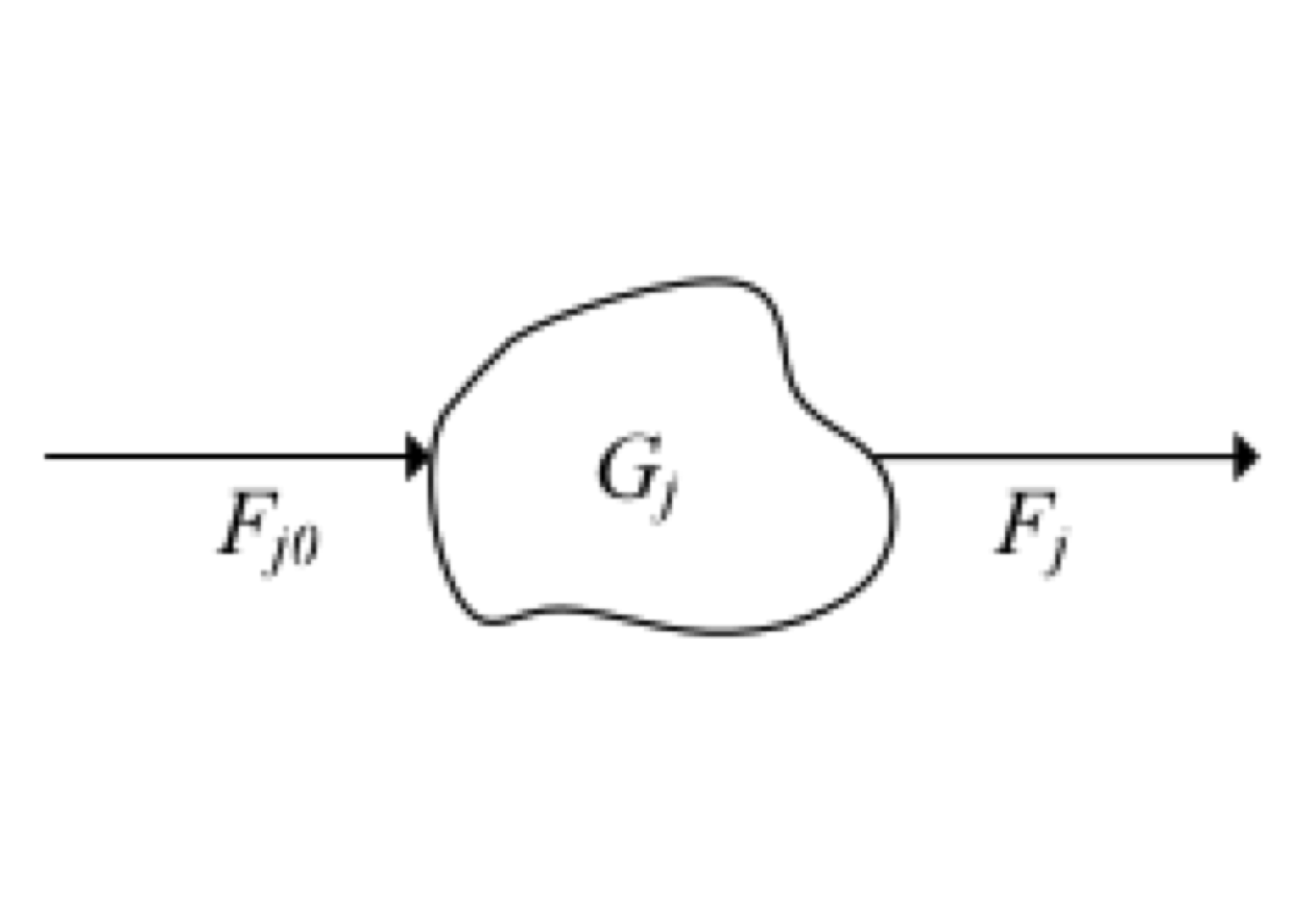

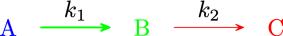

We will perform a mole balance on species \(j\) in a system volume, where \(j\) represents the particular chemical species of interest.

Figure 2.2: System volume scheme

Based on figure 2.2, the mole balance expressed in mole/time would be

\[\begin{equation} F_{j0} + G_j - {F_j } = \frac{dN_j}{dt} \tag{2.1} \end{equation}\] where \(F_{j0}\) is rate flow in \(j\), \(G_j\) is the generation rate of \(j\) by chemical reaction, \(F_{j}\) is rate flow out \(j\), and \(dN_j/dt\) means accumulation rate of \(j\).

In equation (2.1), the generation/consumption of \(j\) (\(G_j\)) will be expressed as the product of the reaction volume, \(V\), and the rate of reaction, \(r\).

The symbol \(r\) is expressed in molar units per unit time and volume, and it is always positive when the reaction proceeds in the direction of the arrow. Thus, the integral form of the general mole balance for any chemical specie \(j\) yields. \[\begin{equation} F_{j0} - F_j + \int_{0}^V {r_j\,dV} = \frac{dN_j}{dt} \tag{2.2} \end{equation}\]

In mathematical terms, the equation (2.2) is called the continuity equation for \(j\). If \(j\) reacts in more than one phase, such an equation is needed for each phase. This equation will develop the design equations for different ideal reactors: batch, semi-batch, and continuous-flow.

The mechanisms by which \(j\) can enter or leave the volume element are flow and molecular diffusion, and they are irrelevant. However, it is essential to realize that a fluid’s motion is not really ordered and challenging to describe.

For this reason, as a first approach, it is therefore natural to consider two extreme conceptual cases: first, where there is no mixing of the streamlines, and second, where the mixing is complete. These two extremes may be formulated with sufficient approximation by the tubular plug flow reactor, and the continuous flow stirred tank with complete mixing.

In a plug flow reactor, all fluids elements move with equal velocity along parallel streamlines. The plug flow is the only mechanism for mass transport, and there is no mixing between fluid elements. The reaction leads to a concentration gradient in the axial flow direction.

Reactors with complete mixing may be subdivided into batch and continuous types. In batch-reactor types with complete mixing, the composition is uniform throughout the reactor. Consequently, the continuity equations may be written for the entire contents, not over a volume element. As the bulk composition varies with time, a first-order ordinary differential equation is obtained, with time as a variable. The form of this equation is analogous to that for the plug flow case.

In the continuous flow type, an element of the entering fluid is instantaneously mixed with the reactor’s contents so that it loses its identity. This type also operates at a constant concentration level. In the steady-state, the continuity equations are algebraic.

Both types of continuous reactors considered are idealized conceptual cases. They are important cases because they are easy to calculate and give the extreme values of the conversions between those realized in a real reactor. With its intermediate level of mixing, the design of a real reactor requires information about this mixing.(Froment, Bischoff, and De Wilde 2011)

2.1.2 Energy Balance

The real chemical reactors are almost operated under nonisothermal conditions because reactions generate or absorb large amounts of heat. Detailed reactor sizing and analysis require the energy balance to be solved in conjunction with one or more material balances.

For a generic open system, the energy balance is: \[\begin{equation*} Q - {W_s} + \dot{H}_\text{in} - \dot{H}_\text{out} = \frac{dE}{dt} \end{equation*}\]

The terms in energy balances have the following meanings:

- \(Q\) is the rate of heat transfer into the reactor.

- \(W_s\) means the rate at which shaft work is done by the system on the surrounding. If shaft work is done on the contents of the reactor, e.g., by an agitator, the value of \(W_s\) is negative.

- \(\dot{H}_\text{in}\) is the rate at which enthalpy is transported into the reactor.

- \(\dot{H}_\text{out}\) is the rate at which enthalpy is transported out of the reactor.

- \(dE/dt\) is the rate at which the system’s total energy, \(E\), changes with time.

In chemical reactors, it is typically assumed the internal energy is the dominant contribution over the kinetic and potential energies. Thus, the general energy balance will be

\[\begin{equation} \frac{dU}{dt}= Q - W_s + \dot{H}_{\text{in}} - \dot{H}_\text{out} \tag{2.3} \end{equation}\]

For single reactors, the inlet and outlet molar flow are related through the extents of reaction (\(\xi\)). If “\(R\)” independent reactions occur, and if the extents of reaction are zero in the stream that enters the reactor.(Roberts 2009)

\[\begin{equation*} F_i - F_{i0} = \sum_{j=1}^{R} \nu_{j,i}\,\xi_j \end{equation*}\] where \(\nu_{j,i}\) refers to stoichiometric coefficient of the component in the reaction .

Therefore, \[\begin{equation*} \dot{H}_{\text{in}} - \dot{H}_{\text{out}} = \sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{H}_{i0} - \sum_{i=1}^{\mathcal{C}} \left(F_{i0} + \sum_{j=1}^{R} \nu_{j,i}\,\xi_j\right)\,\overline{H}_i \end{equation*}\] where \(\overline H_i\) refers to the partial molar enthalpy of the component .

Assuming that feed and product streams are ideal solutions, the partial molar enthalpies \(\overline{H}_i\) can be replaced by pure component enthalpies, \(H_i\), Thus, \[\begin{equation*} \dot{H}_{\text{in}} - \dot{H}_{\text{out}} = \sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\left({H}_{i0} - H_i\right) - {{\sum_{j=1}^R}} \xi_j\,\left(\sum_{i=1}^{\mathcal{C}} \nu_{i,j}\,{H}_i (T)\right) \end{equation*}\] The term \(\sum \nu_{i,j}\,{H}^\circ_i\) is just the enthalpy of reaction for reaction \(j\), evaluated at exit conditions. Since the temperature of the effluent stream is \(T\), \[\begin{equation*} \sum_{i=1}^{\mathcal{C}} \nu_{i,j}\,{H}_i = \Delta H_{R,j}(T) \end{equation*}\] where \(\Delta H_{R_j}(T)\) is the heat of reaction \(j\), evaluated at the temperature \(T\).

If the pressure difference between the feed and the product streams is not substancial, and if there are no phase changes \[\begin{equation*} H_{i0} - H_i = \int_T^{T_0} {C_{P_i}\,dT} \approx \overline{C}_{P_i} \left(T_0 - T\right) \end{equation*}\] where, \(T_0\) is the temperature of the inlet stream, \(C_{P_i}\) is the constant-pressure molar heat capacity of specie i, and \(\overline{C}_{P_i}\) is the average constant-pressure molar heat capacity over the temperature range \(T_0\) to \(T\)

So, eq. (2.3) becomes to \[\begin{equation} \frac{dU}{dt}= Q - W_s - \sum\limits_{i=1}^{\mathcal{C}} \left(F_{i0}\,\int_{T_0}^{T} {C_{P_i}\,dT}\right) - {\sum_{j=1}^R} \xi_j\,\Delta H_{R,j}(T) \tag{2.4} \end{equation}\]

Equation (2.4) is the energy balance for a whole reactor in which multiple reactions are taken place. In this equation, the term \(\left(\sum F_{i0}\,\int{C_{P_i}\,dT}\right)\) represents the rate of sensible heat, and it is usually written on a molar basis. The term \(\sum \xi_j\,\Delta H_{R,j}(T)\)), means the heat rate (generated or consumed) related to the reaction.(Roberts 2009)

If only one reaction is taking place, eq. (2.4) can be written in terms of the fractional conversion. For a single reaction, where \(A\) is a reactant, \[\begin{equation*} \xi = - \frac{F_{A0} - F_A}{\nu_A} = - \frac{F_{A0}\,X_A}{\nu_A} \end{equation*}\]

Substituting this relationship into eq. (2.4) and assuming steady-state condition gives (Roberts 2009)

\[\begin{equation} Q - W_s - \sum\limits_{i=1}^{\mathcal{C}} \left(F_{i0}\,\int_{T_0}^{T} {C_{P_i}\,dT}\right) + F_{A0}\,X_A\,\frac{\Delta H_{R}(T)}{\nu_A} = 0 \tag{2.5} \end{equation}\] or \[\begin{equation*} Q - W_s - \sum\limits_{i=1}^{\mathcal{C}} \left(F_{i0}\,\int_{T_0}^{T} {C_{P_i}\,dT}\right) - \frac{\Delta H_{R}(T)}{\nu_A}\,r_A V =0 \end{equation*}\]

When \(\nu_A = −1\) is chosen, the basis for \(\Delta H_R\) has been fixed to 1 mole of A, i.e., the units of \(\Delta H_R\) must be energy/mole of A

The form of the energy balance results from considerations closely related to those for different continuity equations. When the mixing is so intense that the concentration is uniform over the reactor, it may be accepted that the temperature is also uniform.

When plug flow is postulated, it is natural to accept that the concentration in a section perpendicular to flow is considered to be uniform. It is natural to also consider the temperature to be uniform in this section. It follows that when the heat is exchanged with the surroundings, the temperature gradient has to be situated entirely in a thin “film” along the wall. This also implies that the resistance to heat transfer in the central core is zero in a direction perpendicular to the flow, which is not right for certain catalytic reactors.

2.1.3 Momentum Balance

The momentum balance can be obtained by the application of Newton’s second law on a moving fluid.

In a chemical reactor, only pressure drop and friction forces have to be considered in most cases. Several specific pressure drop equations will be discussed later on PFR and on a fixed catalytic reactor.

2.2 The Continuous-Stirred-Tank Reactor (CSTR)

When the demand for a single chemical product reaches a high level, there will be an economic incentive to continuously manufacture it, using a reactor dedicated to that product. One of those is The Continuous-Stirred-Tank Reactor or CSTR.

The CSTR is a well-mixed vessel consisting of a baffled tank with mixing induced by an impeller and operates at a steady-state. The mass flow rate into the tank is equal to the mass flow rate out of it at steady-state, and the feed and product properties are not functions of time. Furthermore, the reactor volume is constant.

A well-mixed vessel means a working fluid with neither radial, axial, nor angular gradients in properties. In other words, both the composition and temperature of the fluid are uniform over the entire volume. That is, they do not vary with position. Those assumptions are

The central assumption is that the incoming fluid concentration will become instantaneously equal to outgoing upon entering the vessel. As a consequence of well-mixing behavior, the effluent stream must have precisely the same composition and temperature as the contents of the reactor. The feed must be immediately mixed with the reactor’s contents in a time interval that is very small compared to the mean residence time of the fluid flowing through the vessel to meet this ideal mixing pattern. (Froment, Bischoff, and De Wilde 2011)

The CSTR is frequently chosen when temperature control is a critical aspect when the conversion must occur at constant composition, when a reaction between two phases has to be carried out, or when a catalyst must be kept in suspension. (Froment, Bischoff, and De Wilde 2011)

In practice, it is possible to reach a perfect mixing condition if the mixing time is much less than the residence time inside the reactor, usually when the fluid is low viscosity.

2.2.1 The design equation for a CSTR

An ideal CSTR is quite similar to a perfectly mixed batch reactor. The most significant difference is that mass flows into and out of a CSTR. Thus, the mass flow in and out of the reactor in eq. (2.1) will not cancel.

Writing the material balance for this system: \[\begin{equation} \frac{dN_j}{dt} = F_{\text{in},j} - F_{j} + r_j V \tag{2.6} \end{equation}\] where \(F_{\text{in},j}\) is the molar flow in of \(j\), \(F_{j}\)is the molar flow out of \(j\), \(V\) is the reactor volume, \(r_{j}\) is the production rate of specie \(j\), and \(N_{j}\) means the number of moles of specie \(j\)

At steady-state, the left-hand side of eq. (2.6) is zero, thus \[\begin{gather} F_{\text{in},j} - F_{j} + r_j V = 0 \notag \\ V = \frac{F_{\text{in},j} - F_{j}}{- r_j} \tag{2.7} \end{gather}\]

Equation (2.7) is the design equation for an ideal CSTR. For a single reaction, it is useful to write it down in terms of the conversion of reactant A. \[\begin{align*} F_{A,\text{in}} & = F_{A0} {\left(1 - X_{A,\text{in}} \right) }\\ F_{A} & = F_{A0} {\left(1 - X_{A} \right)} \end{align*}\]

leading to \[\begin{equation} \frac{V}{F_{A0}} = \frac{X_{A} - X_{A,\text{in}}}{-r_A}, \quad r_A = - r \tag{2.8} \end{equation}\] where \(\nu_A\) represents moles of A, and \(r\) the global rate equation.

The material balance equation is usually solved for V in steady-state operation or determines the changes of outlet properties concerning time in the unsteady-state process for a particular V.

These characteristics of a CSTR generates an inherent weakness in its operation related to the fractional conversion: \[\begin{equation*} X_A = \frac{C_{A0} - C_A}{C_{A0}} \end{equation*}\]

If a high conversion is desired, the reactant concentration must be small. But the reaction rate depends directly on the reactant concentration, so to compensate for this restriction, we must design larger reactors.

Constant-Density System

If the reactor volume is constant and the volumetric flow rate of the inflow and outflow streams are the same, the eq. (2.6) in terms of volumetric flow rates, is

\[\begin{gather} F_j = \upsilon \,C_j \notag \\ \frac{dC_j}{dt} = \frac{1}{\overline t}\left(C_{j,0} - C_{j} \right)+ r_j \tag{2.9} \end{gather}\] where \(C_{0,j}\) is the concentration of specie \(j\) at initial conditions, \(C_j\) is the concentration into the reactor, and \(\overline t\) is used to refer to the mean residence time, which is given by \[\begin{equation} \overline t = \frac{V}{\upsilon} \tag{2.10} \end{equation}\] where \(\upsilon\) is the volumetric flow rate evaluated at exit conditions.

For \(X_{A,\text{in}} = 0\), the effluent volumetric flow rate can be related to inlet flow rate by \[\begin{equation} \upsilon = \upsilon_0 \left( 1 + \nu\, X_A \right) \tag{2.11} \end{equation}\] where \(\upsilon_0\) is the volumetric flow rate evaluated at entrance conditions, and \(\nu = \sum\nolimits_j \nu_j\)

Since the volumetric flow rate is a function of \(X\), \(T\), and \(P\), the mean residence time, \(\overline t\), depends on those variables. Instead of using the reactor residence time to describe performance, an equal quantity called space-time define as: \[\begin{equation} \tau = \frac{V}{\upsilon_0} \tag{2.12} \end{equation}\] This definition of space-time applies to any continuous reactor.

For a homogeneous reaction, space-time has the dimension of time. It is related to the average time a volume element of fluid spends in the reactor.

Although space-time is not necessarily equal to the mean residence time, they behave similarly, and it is possible to relate eq. (2.10) and eq. (2.12) \[\begin{equation} \overline t = \frac{\tau}{1 + \varepsilon_A\, X_A} \tag{2.13} \end{equation}\]

If the volume change in the reactor is negligible, then \(\varepsilon_A = 0\). Finally, if the working fluid has constant density \[\begin{gather} V = \frac{\left(C_{A0} - C_A\right) \upsilon}{r_A} \notag \\ \overline t = \tau \tag{2.14} \end{gather}\]

Space-time influences reaction behavior in a continuous reactor in the same way that real-time does on a batch reactor’s behavior. In both cases, the fractional conversion will increase if reactants spend more time or space-time increases.

Therefore, if the fluid density is constant, eq. (2.8) becomes \[\begin{equation} \tau = \frac{C_{A0} - C_{A}}{-r_A}, \quad r_A = - r \end{equation}\]

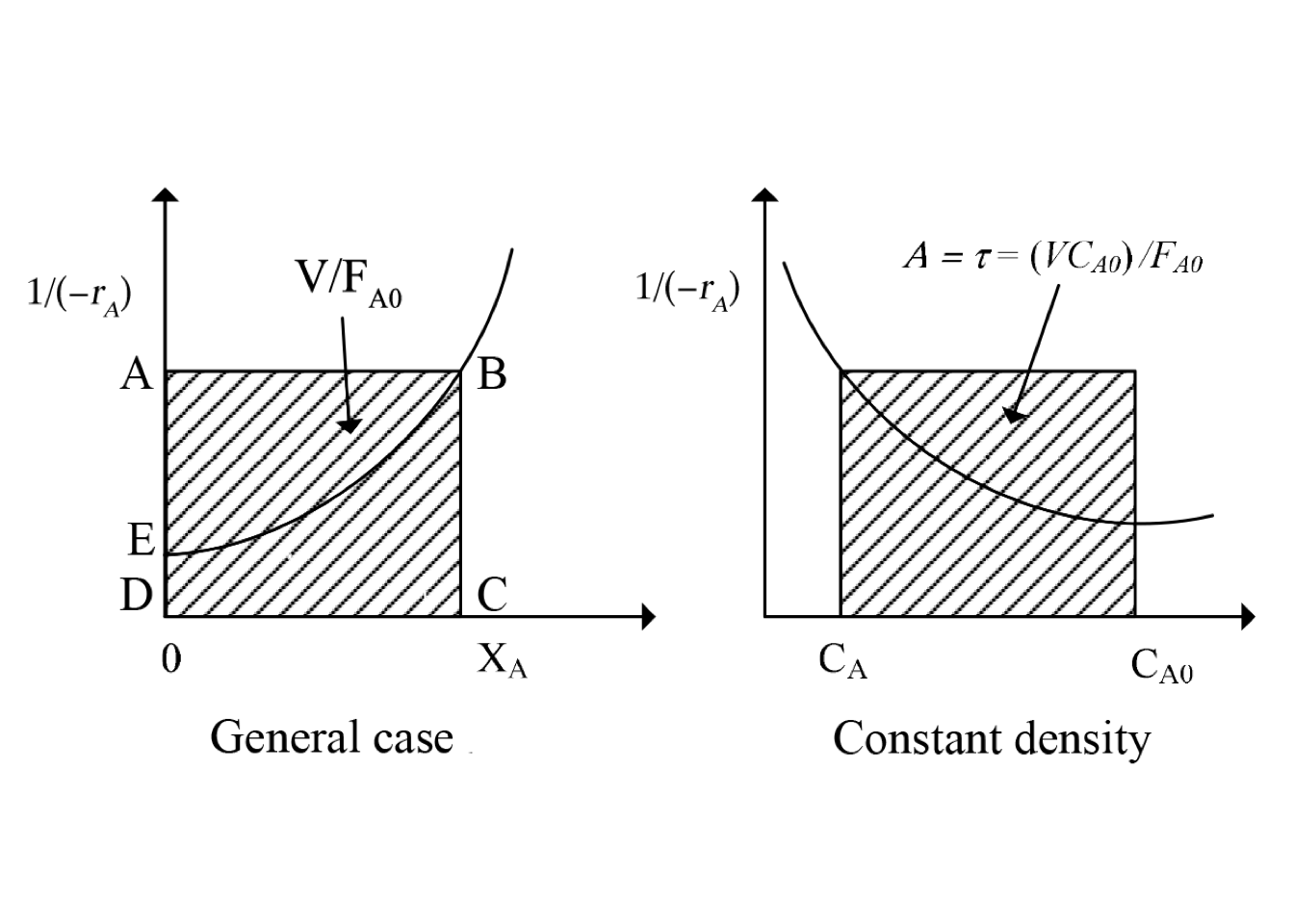

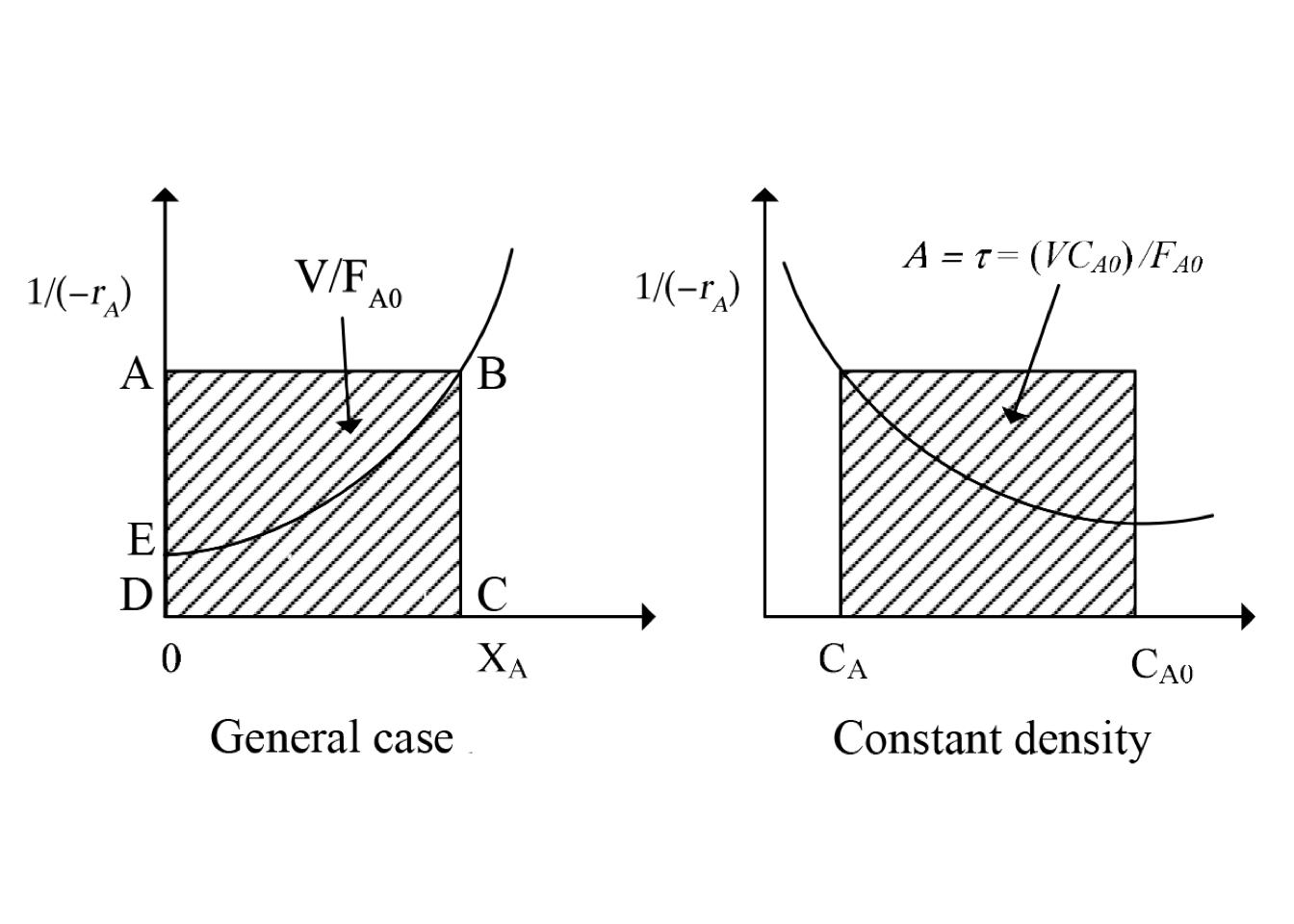

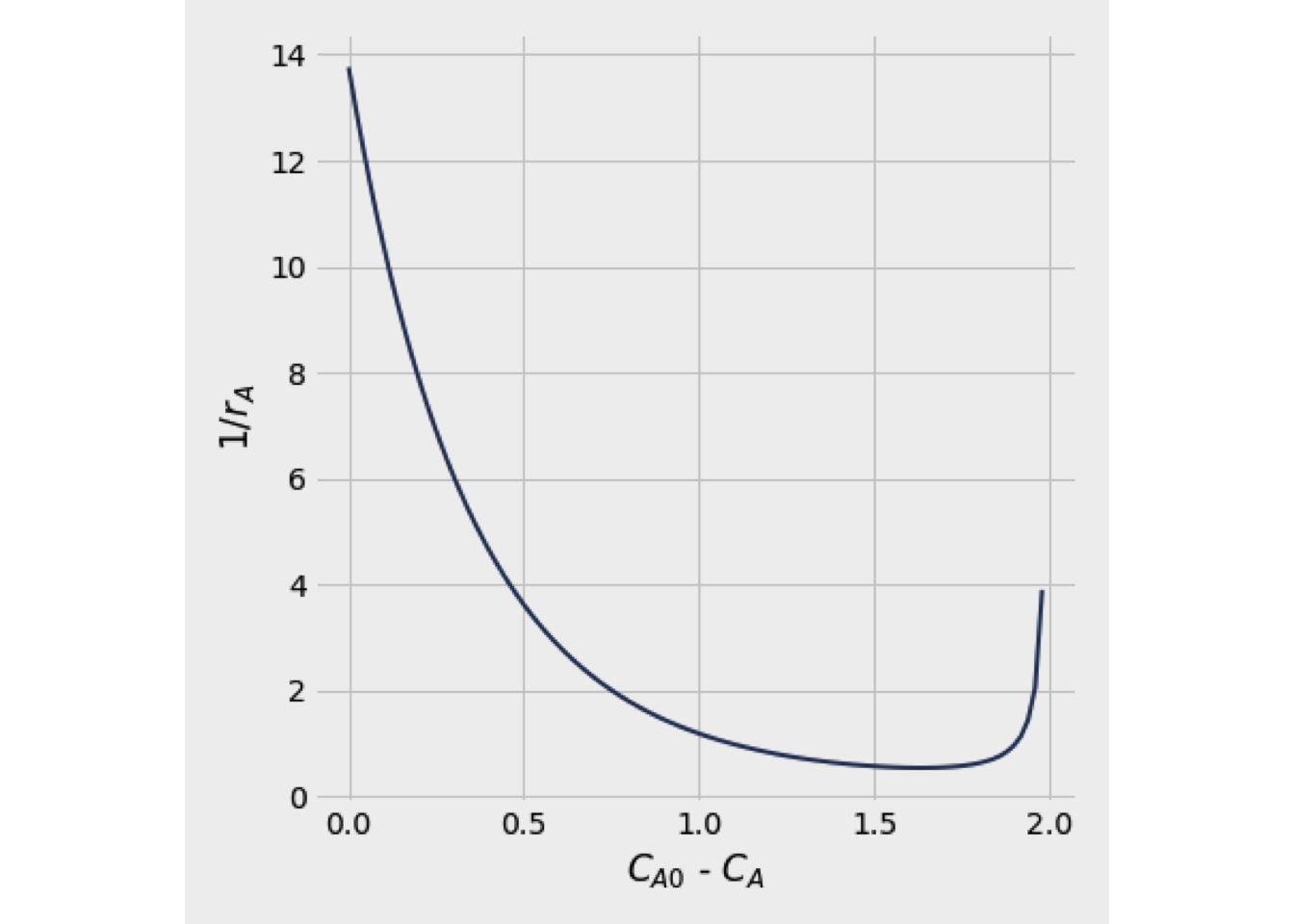

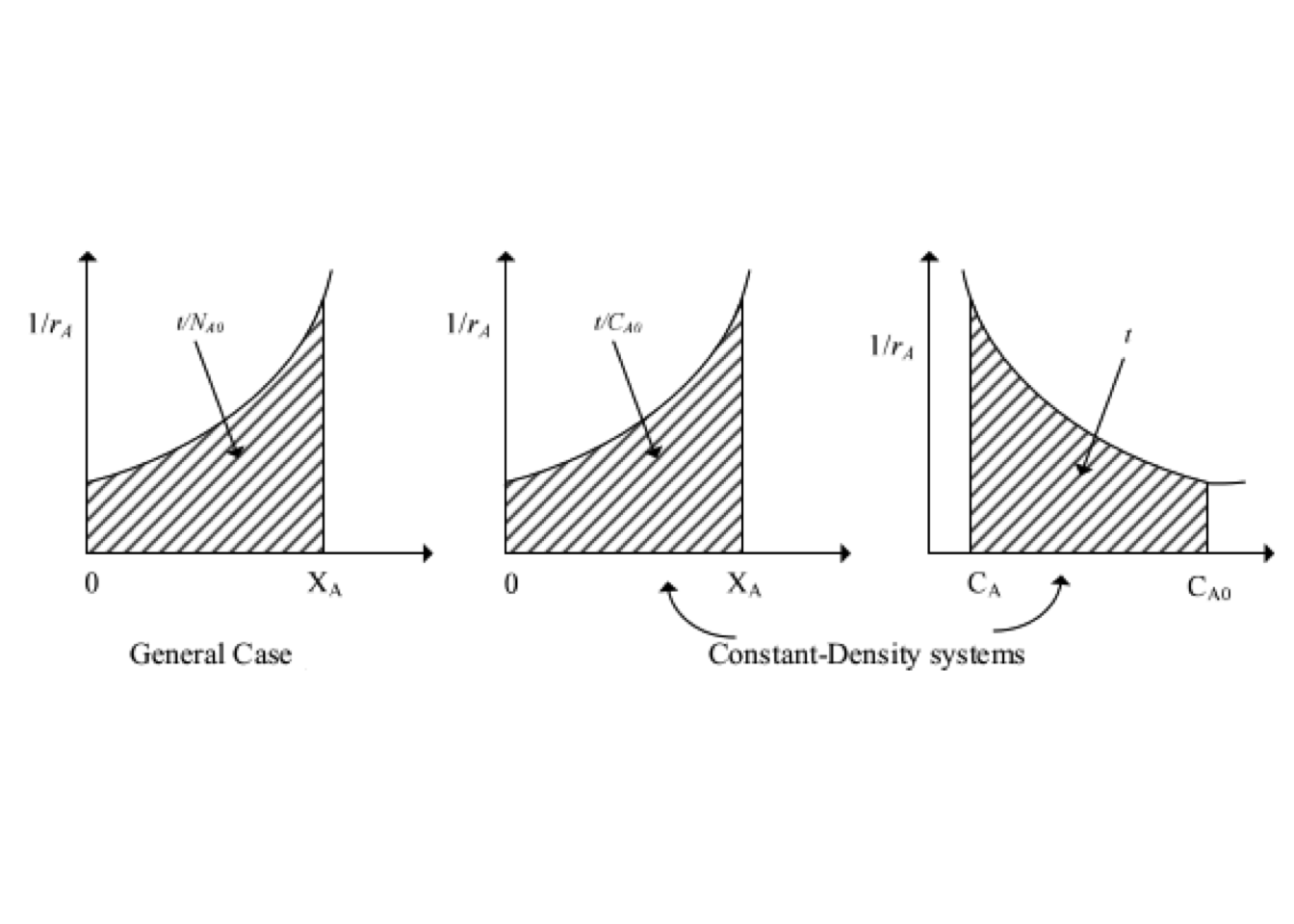

The equation (2.8) may be interpreted graphically from a plot of reciprocal rate \(1/(−r_A)\) as function of \(X_A\), as shown by curve EB in fig. 2.3. Point B is the operating point of the reactor, which represents the steady-state condition in the reactor. Area ABCD represents the ratio \(V/F_{A0}\) for the CSTR.

Figure 2.3: Graphical representation of the performance equations for CSTR

Another parameter commonly used for CSTR design is the inverse of \(\tau\), called space velocity, which can be regarded as the number of reactor volumes of feed processed per unit time at the feed conditions. \[\begin{gather} \text{SV} = \frac{\upsilon_0}{V} = \frac{1}{\tau} \tag{2.15} \end{gather}\]

Space velocity is more useful in the field of heterogeneous catalysis. Its definition is not unique. For example, it can also be defined as GHSV, which means gas-hourly space velocity. It may be defined as the volumetric flow rate of gas entering the catalyst divided by the catalyst’s weight.

Variable-Density System

For variable-density cases, the design equation for a CSTR is: \[\begin{align} \frac{V}{\upsilon} = \tau & = \frac{V}{\upsilon_0 \left( 1 + \varepsilon_A\, X_A \right) } = \frac{C_{A0} - C_A}{r_A(C_A)} \notag \\ \tau & = \left( 1 + \varepsilon_A\, X_A \right)\,\frac{C_{A0} - C_A}{r_A(C_A)} \end{align}\]

2.2.2 CSTR in series

CSTRs of equal sizes in series

Consider a system of \(N\) CSTRs connected in series, as shown in the figure 2.4. Though the concentration is uniform in each reactor, there is a change in concentration as fluid moves from one reactor to another.

Figure 2.4: Sketch of ideal CSTRs in series

The feed molar flow rate of reactant A is \(F_{A0}\), the effluent conversion of A from the first reactor is \(X_{A1}\), while the output conversion of A from the second reactor is \(X_{A2}\) so on.

It is crucial to be consistent in defining the fractional conversion for a series of reactors.

For a series of three CSRTs in serie \[\begin{align*} X_{A,1} = \left(F_{A0} - F_{A,1} \right)/(F_{A0}) \\ X_{A,2} = \left(F_{A0} - F_{A,2} \right)/(F_{A0}) \\ X_{A,3} = \left(F_{A0} - F_{A,3} \right)/(F_{A0}) \end{align*}\]

The conversion \(X_{A1}\) is the fractional conversion of A in the stream leaving the first reactor. In contrast, \(X_A2\) is the overall conversion of A in the second reactor’s effluent, which means the conversion for the first and second reactors combined. Thus, the overall conversion for the series of three CSTRs is equal to \(X_{A3}\). (Roberts 2009)

The mole balance for reactant \(A\) can be written for any reactor \(j\) in the series will be \[\begin{equation} - r_{A,j} = \frac{F_{A,j-1} - F_{A,j}}{V_j} \end{equation}\]

The molar flow rates from a reactor \(j\) and \(j-1\) expressed in terms of conversion are: \[\begin{align*} F_{A,j-1} & = F_{A0} {\left(1 - X_{A,j-1} \right) }\\ F_{A,j} & = F_{A0} {\left(1 - X_{A,j} \right)} \end{align*}\]

The change in the molar flow rate of A in any reactor is defined as \[\begin{equation*} F_{A,j-1} - F_{A,j} = F_{A0}\left(X_{A,j} - X_{A,j-1}\right) \end{equation*}\]

Therefore, the design equation for a reactor \(j\) is written in terms of conversion as: \[\begin{equation} \frac{V_j}{F_{A0}}= \frac{\left(X_{A,j} - X_{A,j-1}\right)}{- r_A\left(X_{A,j}\right)} \tag{2.16} \end{equation}\]

This equation can be rearranged in terms of the conversion from reactor \(j\) \[\begin{equation} X_{A,j} = X_{A,j-1} - \frac{r_{A,j}\:V_j}{F_{A0}} \tag{2.17} \end{equation}\]

Equation (2.17) can be solved for each reactor sequentially to calculate the incremental conversion from each reactor. Equation (2.18) can be generalized to apply to the Nth reactor in a series of CSTRs

\[\begin{equation} \frac{V_N}{F_{A0}}= \frac{\left(X_{A,N} - X_{A,N-1}\right)}{- r_A\left(X_{A,N}\right)} \tag{2.18} \end{equation}\]

A typical case is to evaluate the behavior of a series of N equal-size CSTRs that operate isothermally, with a first-order kinetic and no volume change \(\left( \upsilon = \upsilon_0 \right)\).

In this case, it is convenient to write mass balances on specie A in terms of concentrations and \(\tau\) instead of fractional conversion.

\[\begin{align*} C_{A0} - C_{A1} &= \tau_1\,r (C_{A1}) \\ C_{A1} - C_{A2} &= \tau_2\,r (C_{A2}) \\ C_{A2} - C_{A3} &= \tau_3\,r (C_{A3}) \\ &\vdots \\ C_{A,n-1} - C_{An} &= \tau_n\,r (C_{An}) \end{align*}\]

Usually the initial concentration of A is known. Therefore, the system of equations can be rewritten as: \[\begin{align*} C_{A1} &= \frac{C_{A0}}{\left( 1 + \tau_1 k \right)} \\ C_{A2} &= \frac{C_{A0}}{\left( 1 + \tau_1\, k\right)\left( 1 + \tau_2\, k\right)} \\ &\vdots \\ C_{Ai} &= \frac{C_{A(i-1)}}{\left( 1 + \tau_i\, k\right)} = \frac{C_{A0}}{\prod_k \left( 1 + \tau_k\, k\right)} \end{align*}\]

In general, \[\begin{equation} \frac{C_{A,i-1}}{C_{A,i}} = 1 + k\,\tau_i \qquad \text{or} \qquad \tau_i = \frac{C_{A,i-1}-C_{A,i}}{k\,C_{A,i}} \tag{2.19} \end{equation}\]

Assuming all reactors have the same volume (\(V_i\)), which means they have the same \(\tau\), then the total residence time in the series of N equal-residence-time CSTR is equal \(\sum\nolimits_{k} \tau_{k} = N\, \tau\) and \(C_{A,N}\), the concentration from the N-th reactor is given in terms of \(C_{A0}\) by:

\[\begin{equation} \frac{C_{A,N}}{C_{A0}} = \frac{C_{A,1}}{C_{A0}} \frac{C_{A,2}}{C_{A,1}} \cdots \frac{C_{A,N-1}}{C_{A,N}} = \frac{1}{{\left( 1 + \tau_N\, k\right)}^N} \tag{2.20} \end{equation}\]

Substituting for \(C_{A,N}\) in terms of conversion \[\begin{equation} C_{A0}\:{\left(1 - X_{A,N} \right)} = \frac{C_{A0}}{{\left( 1 + \tau_N\, k \right)}^N} \Rightarrow X_{A,N} = 1 - \frac{1}{{\left( 1 + \tau_N\, k\right)}^N} \tag{2.21} \end{equation}\]

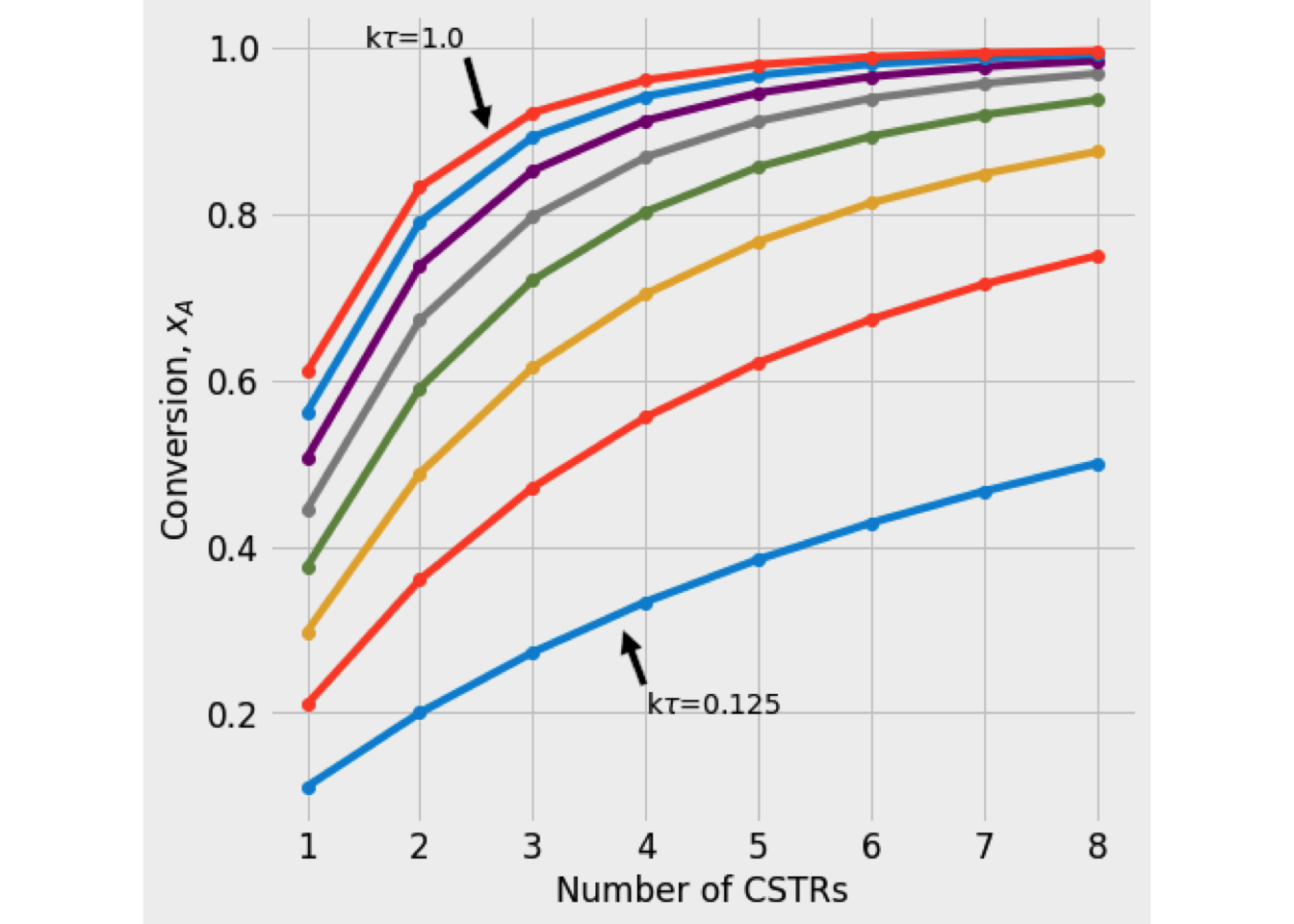

Figure 2.5 shows the variation of conversion vs. the number of reactors in series for a first-order reaction. It also indicates that the Damkholer number is a crucial parameter to decide the optimal number of CSTRs required to reach an overall conversion.

Figure 2.5: Plot of conversion as function of number of CSTRs in serie

In general, while the Damkholer number increases, the system will require fewer CSTRs to get the desired level of conversion. (Numerical solution)

The total capital cost is an important parameter rather than the total reactor volume in a practical situation. Increasing the number of CSTRs in series will reduce the total cost by reducing the required volume. However, it will also increase the price since more agitators, valves, piping, etc., will be required. The economic optimum usually occurs at a value of \(N\) as low as 2 or 3. (Roberts 2009)

The optimal operation of a multistage CSTR can be considered from the point of view of minimizing the total volume V for a given throughput (\(F_{A0}\)) and fractional conversion (\(X_A\)). So it will be necessary an objective function for \(V\) from the material balance together with a rate law and energy balance as required

CSTRs of different sizes in series

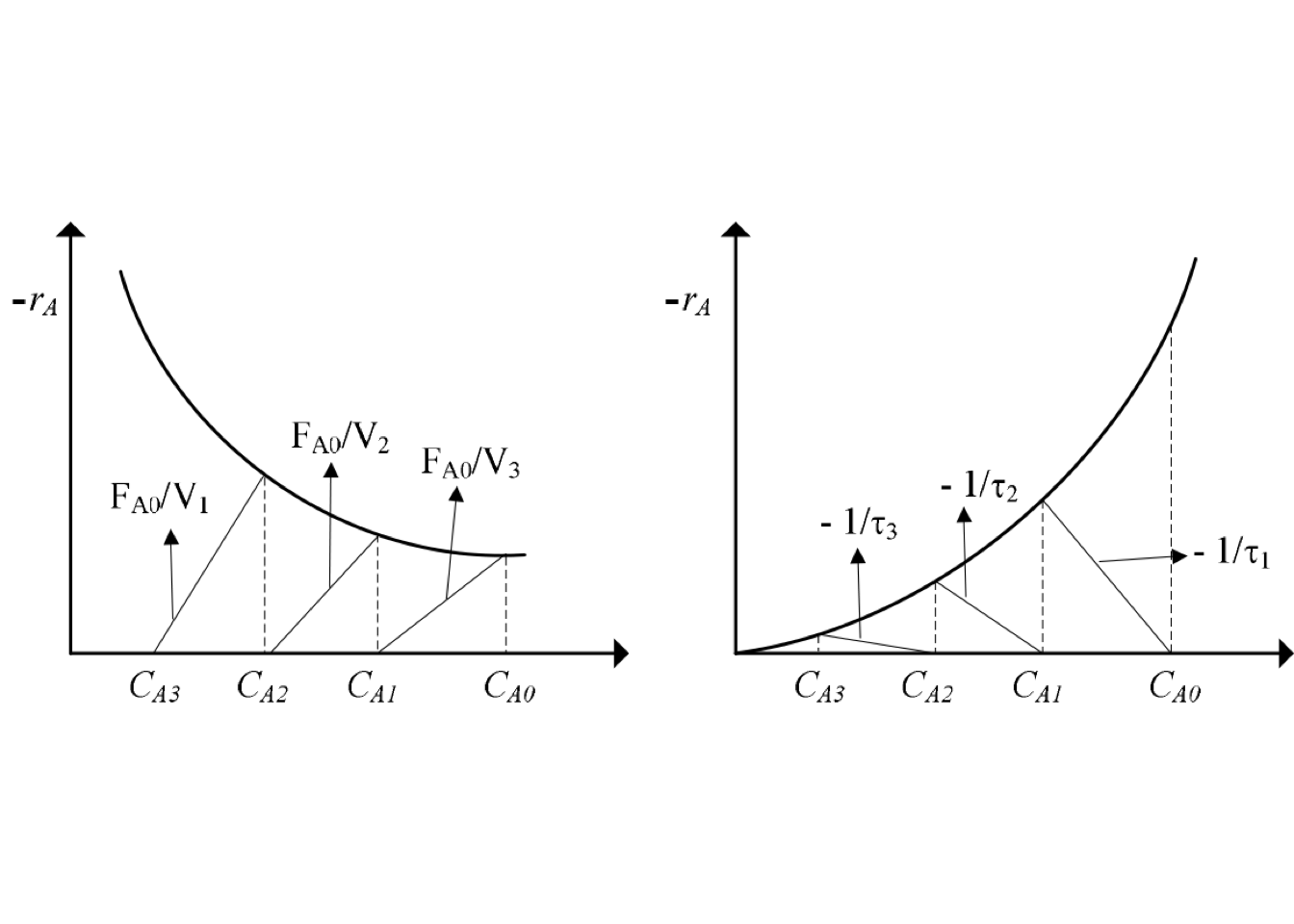

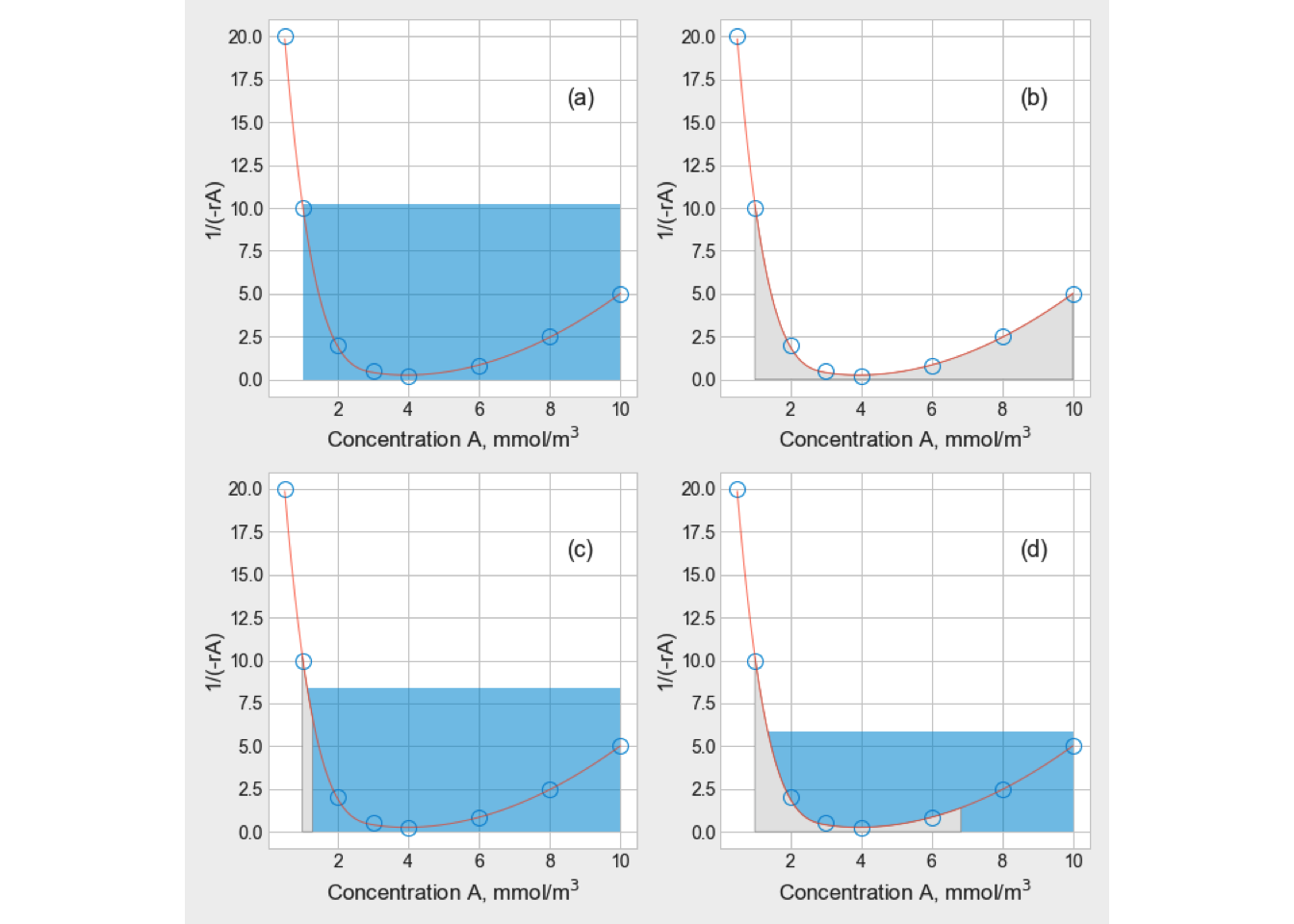

For reactions with slight density change is possible to find the outlet composition from a series of CSTRs by a graphical procedure due to the design equation of each CSTRs could be written as: \[\begin{equation} -\frac{1}{\tau_N} = \frac{(-r_A)_N}{C_{A,N} - C_{A,N-1}} \end{equation}\]

Figure 2.6: Graphical solution for multistage CSTRs - first-order reaction

Figure 2.6 shows a way to represent the material balances for each stage from a plot \(1/(-r_A)\) as a function of \(C_A\).

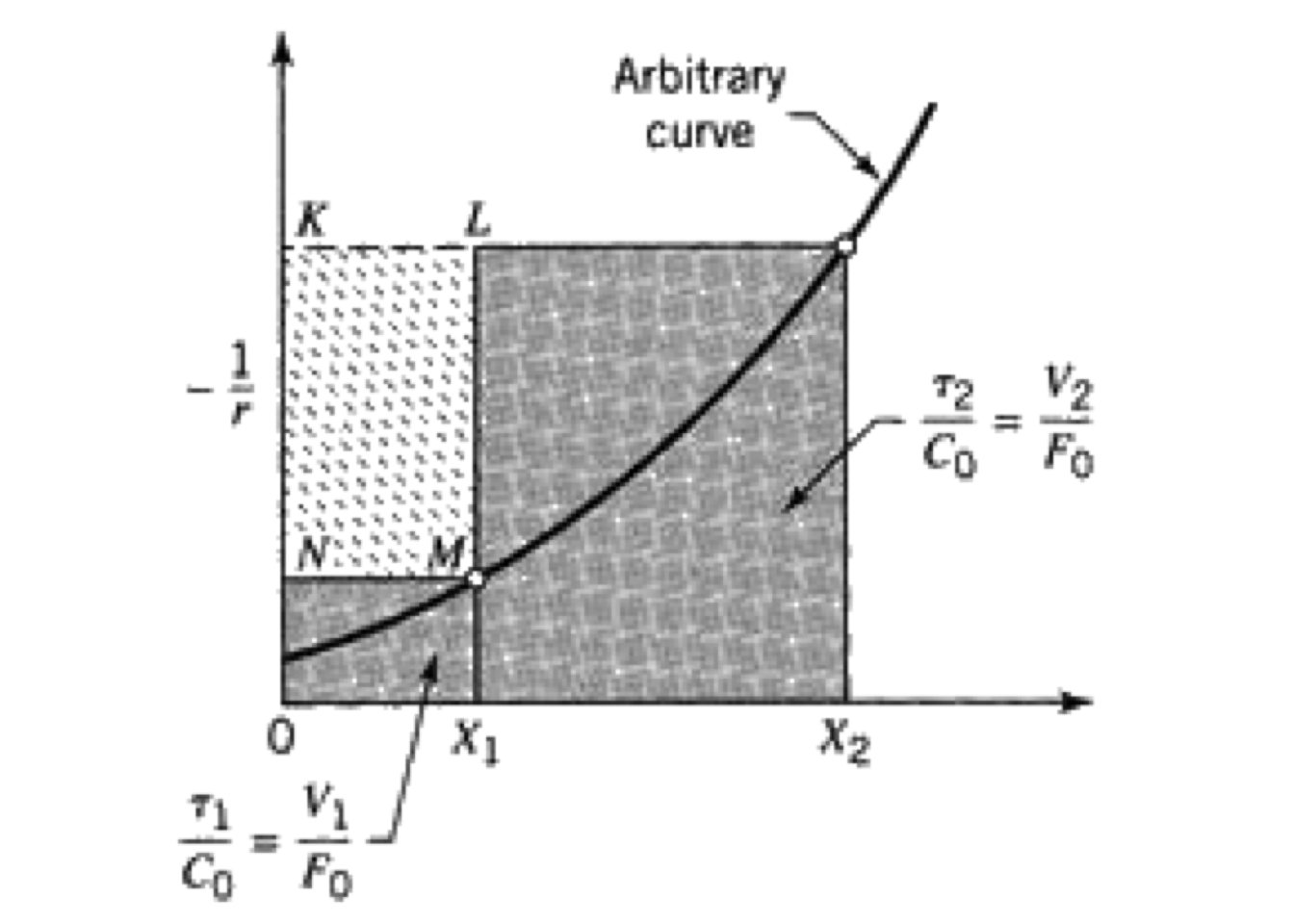

Another interesting situation is finding the best setup to achieve a given conversion. Let us illustrate the use of this method considering two CSTRs in series under isothermal conditions, as shown in the Figure 2.7

Figure 2.7: Graphical representation of two CSTRs in series

For the first CSTR, the design equation becomes \[\begin{equation} \frac{V_1}{F_{A0}} = \frac{X_{A1}}{-r_A(X_{A1})} \end{equation}\]

while for the second one is: \[\begin{equation} \frac{V_2}{F_{A0}} = \frac{X_{A2} - X_{A1}}{-r_A(X_{A2})} \end{equation}\]

These relations are graphically represented in the Figure 2.8. The cascade of CSTRs operates between known initial and final conversion levels, and the total reaction volume is represented by the sum of the shaded areas.

Figure 2.8: Graphical representation of two CSTRs in series

When the rectangle KLMN is made as large as possible, the overall volume is minimized. Therefore, point \(X_{A1}\) is the critical parameter to get the reactors’ optimal size.

For reaction rate expressions of the _n_th-order form, it can be shown that there is always one and only one point that minimizes the total volume when \(n>0\). (C. G. J. Hill and Root 2014)

The total reaction volume is: \[\begin{equation} V_1 + V_2 = F_{A0}\:\frac{X_{A1}}{(-r_A)_1} + F_{A0}\:\frac{X_{A2} - X_{A1}}{(-r_A)_2} \tag{2.22} \end{equation}\]

The derivative of eq. #ref(eq:totalVolume) respects to \(X_{A1}\) is: \[\begin{equation} \frac{d\:\left(V_1 + V_2\right)}{dX_{A1}} = \frac{F_{A0}}{(-r_A)_1} + F_{A0}\:X_{A1}\left(\frac{d\:\left(1/(-r_A)_1\right)}{dX_{A1}}\right) - \frac{F_{A0}}{(-r_A)_2} = 0 \end{equation}\] simplifying leads to \[\begin{equation} \frac{d\left(1/(-r_A)_1\right)}{dX_{A1}} = \frac{1/(-r_A)_2 - 1/(-r_A)_1}{dX_{A1}} \end{equation}\]

Therefore, the minimum reaction volume will be found when the intermediate fractional conversion \(X_{A1}\) is selected. The slope of the reaction rate curve at this conversion level is equal to the slope of the rectangle’s diagonal KLMN, as is shown in figure 2.9.

Figure 2.9: Graphical representation of the minimum total reaction volume for two CSTRs in series

Generally, the optimum size ratio is dependent on the form of the reaction rate expression and on the conversion task specified. Table 2.1 summarizes the optimal configuration for CSTRs in series from a kinetic-order point of view.

| kinetic-order n | Optimal configuration |

|---|---|

| \(n = 1\) | same size |

| \(n > 1\) | first tank with < volume |

| \(n < 1\) | first tank with > volume |

In engineering practice, the designer tends to select CSTRs with the same volume to minimize installation and operational costs.

2.2.3 Energy Balance

Now let us find out how to apply the general energy balance (eq.(2.3)) to a CSTR. Usually, for an ideal CSTR operating at a steady-state (\(dU/dt = 0\)), it is considered the work done by the stirrer neglected, so the energy balance yields to:

\[\begin{equation} Q - \sum\limits_{i=1}^{\mathcal{C}} F_{i0} \left( \int_{T_0}^{T} C_{P_i} dT \right) - \sum\limits_{j = 1}^r \xi_j \, \Delta H_{R_j}(T) = 0 \tag{2.23} \end{equation}\] From thermodynamics, we know that for a reaction \(j\) \[\begin{equation} \xi_j = \frac{F_i - F_{i0}}{\nu_i} = - \frac{F_{i,0}\,X_i}{\nu_i} \end{equation}\]

Thus \[\begin{equation} Q - \sum\limits_{i=1}^{\mathcal{C}} F_{i0} \left( \int_{T_0}^{T} C_{P_i} dT \right) + \sum\limits_{j = 1}^R {\left(\frac{F_{i,0}\,X_i}{\nu_i}\right)}_j \, \Delta H_{R_j}(T) = 0 \tag{2.24} \end{equation}\]

This equation written for a reactant A (\(\nu_A=-1\)), considering only one chemical reaction is taken place, becomes to \[\begin{equation} Q - \sum\limits_{i=1}^{\mathcal{C}} F_{i0} \left( \int_{T_0}^{T} C_{P_i} dT \right) - F_{A,0}\,X_A \, \Delta H_{R}(T) = 0 \tag{2.25} \end{equation}\] or \[\begin{equation} Q - \sum\limits_{i=1}^{\mathcal{C} F_{i0}} \left( \int_{T_0}^{T} C_{P_i} dT \right) + \Delta H_{R}(T)\,r_A\,V = 0 \tag{2.26} \end{equation}\]

while for a product \(P\) \[\begin{equation} Q - \sum\limits_{i=1}^{\mathcal{C}} F_{i0} \left( \int_{T_0}^{T} C_{P_i} dT \right) + \frac{\nu_P}{\nu_A}\,F_{A,0}\,X_A \, \Delta H_{R}(T) = 0 \tag{2.27} \end{equation}\]

Equation (2.25) (or (2.27)), if the system’s heat transfer characteristic is known, requires a reaction rate expression and the design equation to determine the fluid’s temperature and composition leaving the reactor.

Using the energy balance to analyze the performance or sizing an ideal CSTR is not as complicated mathematically, so let us consider some typical heat transfer modes.

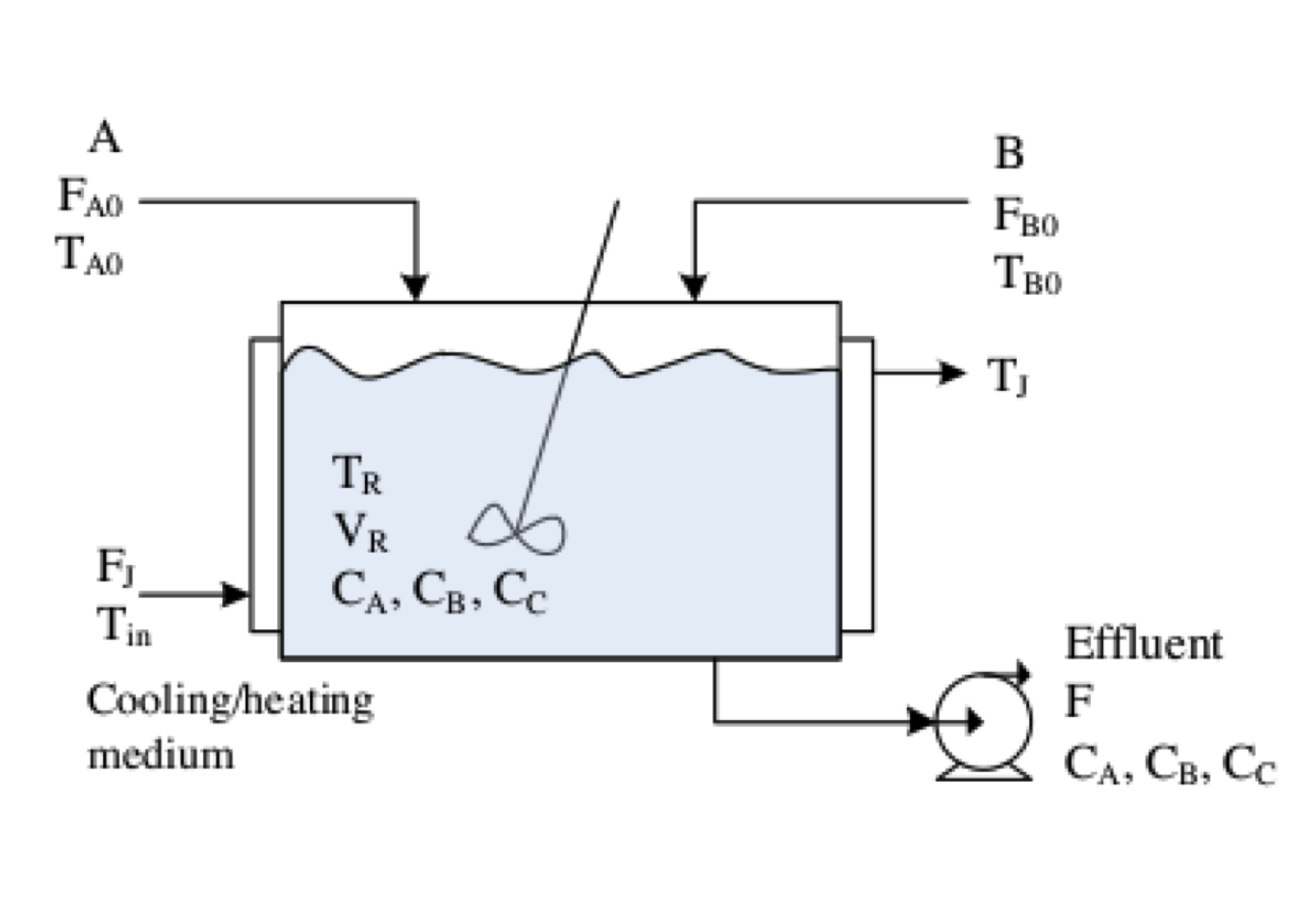

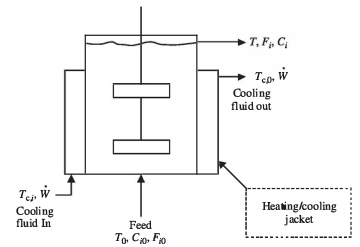

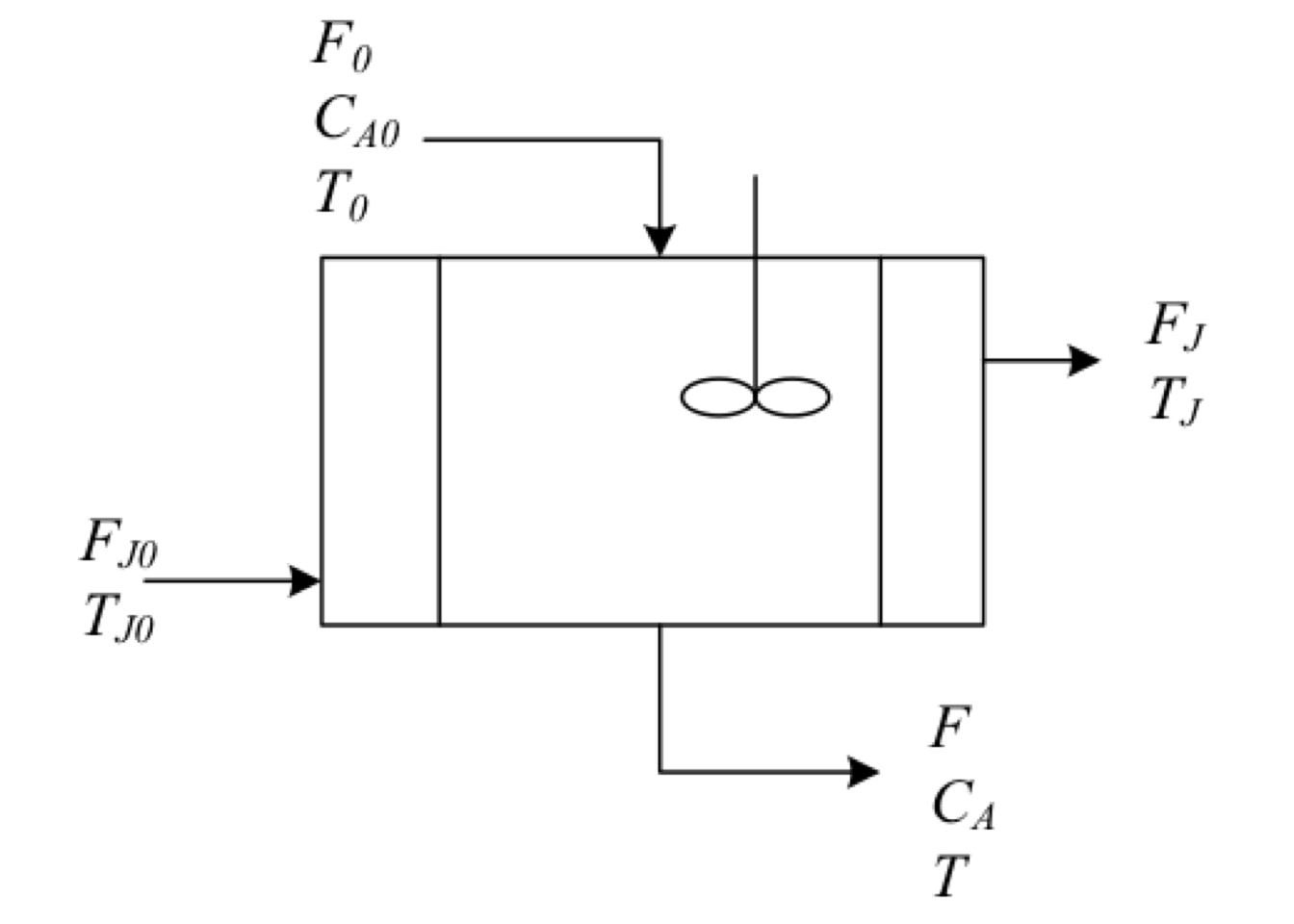

Jacket-Cooled

Consider the ideal CSTR shown in Figure 2.10. Heat is added to or removed from the reactor by a heat-transfer fluid that flows through the jacket. Depending on the reactor temperature and whether the reactor is being heated or cooled, the heat-transfer fluid may be cooling water, chilled brine, chilled glycol solution, hot oil, or some other fluid. The fluid is a source of (or a sink for) the heat transferred through the reactor wall.

Figure 2.10: Schematic diagram of an ideal CSTR with heat transfer through a heating/cooling jacket

The transit energy rate is \(\dot{W}\). The temperature of the fluid at a point in the jacket is \(T_c\). The fluid enters the jacket at \(T_{c,i}\) and leaves at \(T_{c,o}\). The feed enters the reactor at temperature \(T_0\). The molar flow rates of each component of the feed are designated \(F_{i,0}\), and its corresponding concentrations are designated \(C_{i,0}\). The reactor operates at a temperature, T, which is the effluent temperature too. The molar flow rates in the output stream are designated \(F_i\), and the corresponding concentrations are \(C_i\).

If a single reaction occurs in a CSTR and one mole of reactant A is consumed in an elemental first-order reaction, the eq. (2.28) yields to: \[\begin{equation} Q - \left(\sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{C}_{p,i}\right)\left(T - T_0\right) - F_{A0}\,X_A \, \Delta H_{R}(T) = 0 \tag{2.28} \end{equation}\]

The Q term in eq. (2.28) depends on the removal scheme used. In general, the rate for heat transfer is: \[\begin{equation*} q = U \left(T_c - T\right) \end{equation*}\] where: q is the heat flux into the reactor \(\left(\text{J}/\text{m}^2-\text{h}\right)\), and U means the overall heat-transfer coefficient \(\left(\text{J}/\text{m}^2-\text{h}-\text{K}\right)\).

If \(T<Tc\), heat is transferred into the reactor and \(q>0\). The total heat transfer rate, Q, is obtained by integrating the flux, q, over the whole area of the exchanger. For example, if the temperature of the fluid is the same at every point in the exchanger. \[\begin{equation*} Q = U\,A_{J} \left(\overline{T}_c - T\right) \end{equation*}\] where \(\overline{T}_c\) is the constant temperature of the heat-transfer fluid, and it is equal to the outlet temperature, \(T_{c,o}\), \(A_J\) is the total area of the heat exchanger.

Substituting in (2.28), \[\begin{equation} - F_{A0}\,X_A \, \Delta H_{R}(T) = U\,A_{J} \left(T - T_c\right) + \left(\sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{C}_{p,i}\right)\left(T - T_0\right) \tag{2.29} \end{equation}\]

To understand the physical meaning of the terms in eq. (2.29), consider an exothermic reaction. The term \(\left[- F_{A0}\,X_A \, \Delta H_{R}^\circ(T)\right]\) represents the enthalpy change related to change in composition because of the chemical reaction. While \(U\,A_{J} \left(T - T_c\right)\) is the rate at which heat is transferred out of the CSTR. Finally, \(\left(\sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{C}_{p,i}\right)\left(T - T_0\right)\) represents the increase in sensible heat of the feed as it goes from \(T_0\) to T.

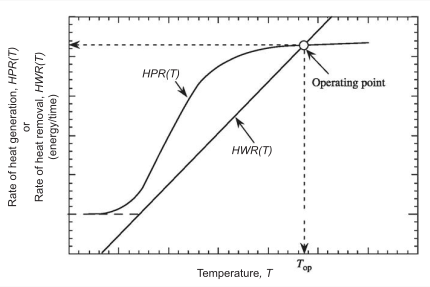

Now, we define two functions corresponding to the left-hand side and right-hand of eq. (2.29), respectively.

The first function is: \[\begin{equation} HPR(T) = - F_{A0}\,X_A\,\Delta H_R(T) \tag{2.30} \end{equation}\]

The function HPR(T) represents the **heat generation* rate in the reactor, proportional to the reaction heat (\(\Delta H_R\)) and conversion degree (\(X_A\)). For an exothermic reaction, this term will be > 0 and a strong temperature function.

The second function, HWR(T), is defined from two right-hands terms of the eq. (2.31). \[\begin{equation} HWR(T) = UA_{J} \left(T - T_c\right) + \left(\sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{C}_{p,i}\right)\left(T - T_0\right) \tag{2.31} \end{equation}\]

Eq (2.31) is called the removal term because it represents the total heat transfer rate per unit volume of the reaction mixture. In summary, it represents the sensible heat from \(T_0\) to T and the heat transferred to the heat-transfer fluid.

Both HPR(T) and HWR(T) allow identifying when the CSRT operates under steady-state conditions and which of them is stable. If HPR(T) \(\neq\) HWR(T), the CSTR is not at steady-state.

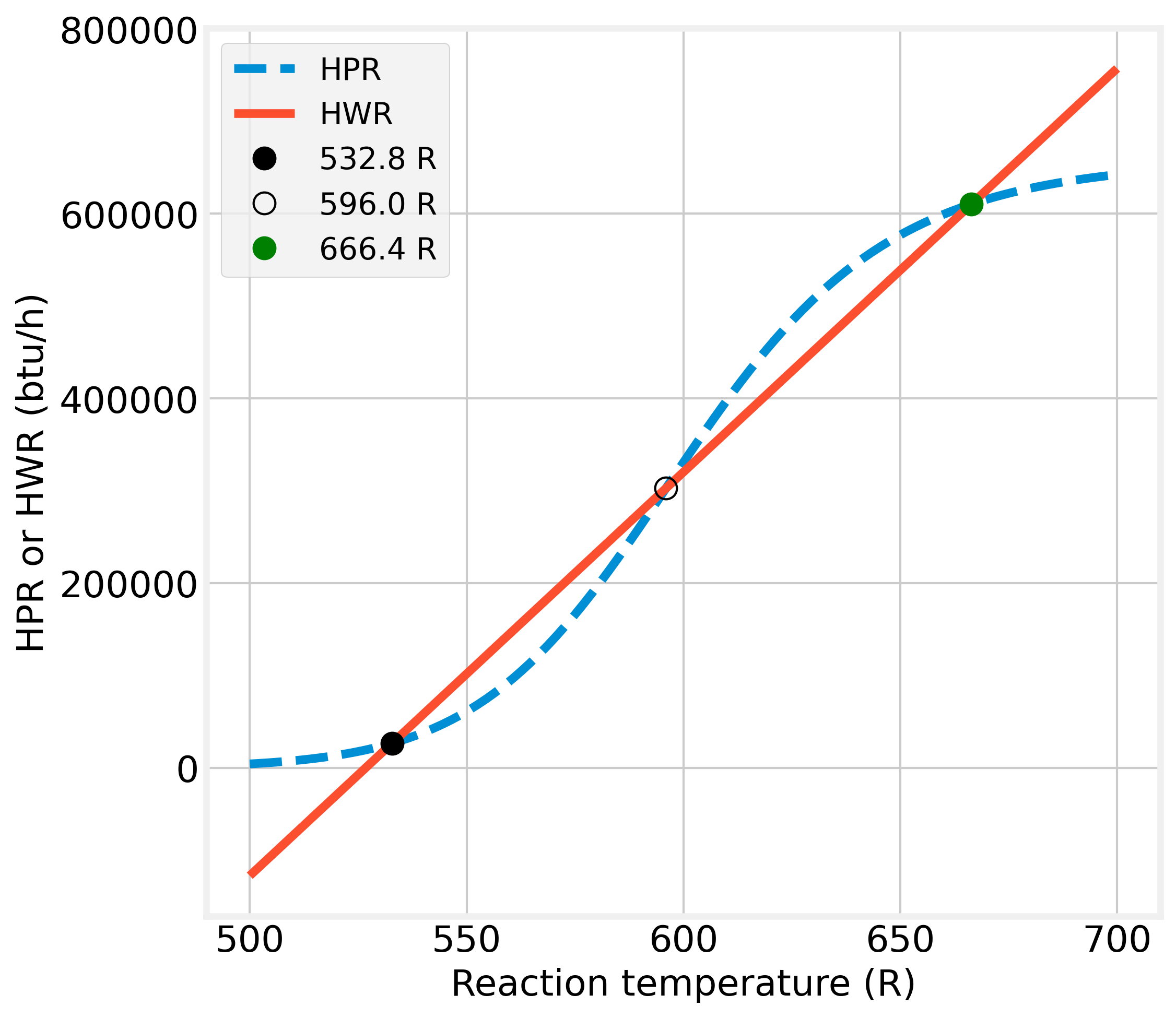

Figure 2.11 shows a typical HPR(T) and HRW(T) vs T plot for an ideal CSTR, assuming an irreversible, exothermic and first-order reaction is taking place.

Figure 2.11: Typical \(HPR(T)\) and \(HWR(T)\) curves versus temperature, \(T\), for an irreversible, exothermic reaction in an ideal CSTR

The intersection of the HPR(T) curve with the HWR(T) line is the reactor’s operating point. Therefore it is a graphical solution to the design equation and the energy balance for the CSTR.

The is linear when \(C_P\) is assumed constant, while the curve is generated following pseudo-algorithm:

OUTPUT: HPR-HWR curve;

WHILE output is not generated

select T from input;

calculate kinetic constants with input;

solve design equation for \(X_A\);

calculate HPR(T)

plot HPR(T) vs. T

IF output_is_True:

end;

For reasons of convenience, several different expressions for heat production and heat removal are used. For the heat production with constant density reactions, we have:

- the heat production per unit time: \(\left(-\Delta H_r\right) \upsilon C_{A0} X_A\)

- the heat production per unit of volume of reaction mixture: \(\left(-\Delta H_r\right) C_{A0} X_A\)

- the heat production per unit of volume of reaction mixture divided by \(\rho C_P\), the sensible heat per unit of volume of the reaction: \(\left(-\Delta H_r\right) C_{A0} X_A/\rho C_P\). This represents the fraction of the maximum possible temperature increase, which is reached in the reactor.

For heat removal, similar expressions can be defined. As long as the HPR and HWR are unit-consistent, all will lead to the same conclusions concerning the reactor design and operation. (Westertep, Van Swaaij, and Beenackers 1984)

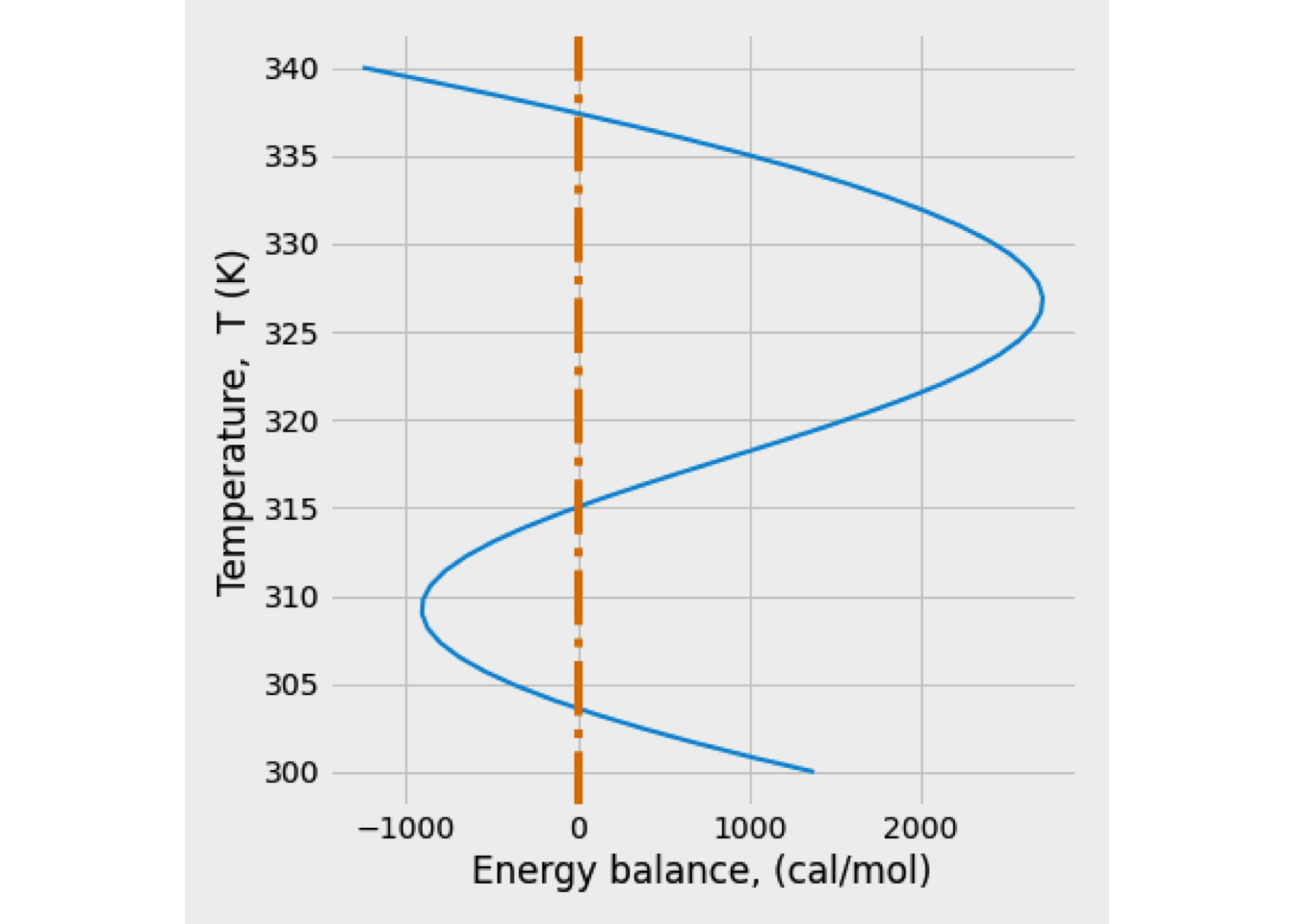

Multiple steady-states analysis

Another essential aspect of CSRT design is to determine if multiple steady-states are raised. This situation is possible because a non-linear equation can have more than one solution. Nevertheless, how is it possible to determine this particular situation?

Let us consider some changes to the situation shown in Figure 2.11. Suppose that the temperature of the feed, \(T_0\), or the cooling fluid temperature, Tc, is reduced. The result of this modification will be to increase the intercept of the HWR(T) line on the y-axis without changing the slope of the line. It means that HWR(T) line shifts to the left, parallel to the original curve, so that it could be more than one operating point. This situation is known as multiple steady-states

In order to determine if there are multiple steady-states for a CSTR. We are going to follow the next steps:

- Let us fixed inlet conditions.

- Let us establish a range for T we are interested in.

- For each T in the temperature range, let calculate k and \(X_A\) (or \(C_A\)).

- Again, for each T, the cooling fluid temperature Tc is calculated.

- Finally, the set of values for T, \(X_A\), and Tc is substituted into the reactor energy balance. When the left-hand side of equation (2.28) is equal to 0, a steady-state will have been reached.

The heat-transfer fluid consumption is calculated from an energy balance around the perfectly mixed jacket at temperature \(T_J\). Constant physical properties of the cooling medium are assumed.

\[\begin{equation} F_c\,\rho_c\,C_{P_c} T_{c,\text{in}} = F_c\,\rho_c\,C_{P_c} T_J - Q \tag{2.32} \end{equation}\] where \(F_c\) is flow rate of coolant \(\left(\text{m}^{3}/\text{s}\right)\), \(\rho_{c}\) means density of coolant \(\left(\text{kg}/\text{m}^{3}\right)\), \(C_{P_c}\) is heat capacity of coolant \(\left(\text{J}\,\text{kg}^{-1}\,\text{K}^{-1}\right)\), \(T_{c,\text{in}}\) represents the supply temperature of cooling medium (K), and \(T_{J}\) is the output temperature of cooling medium (K).

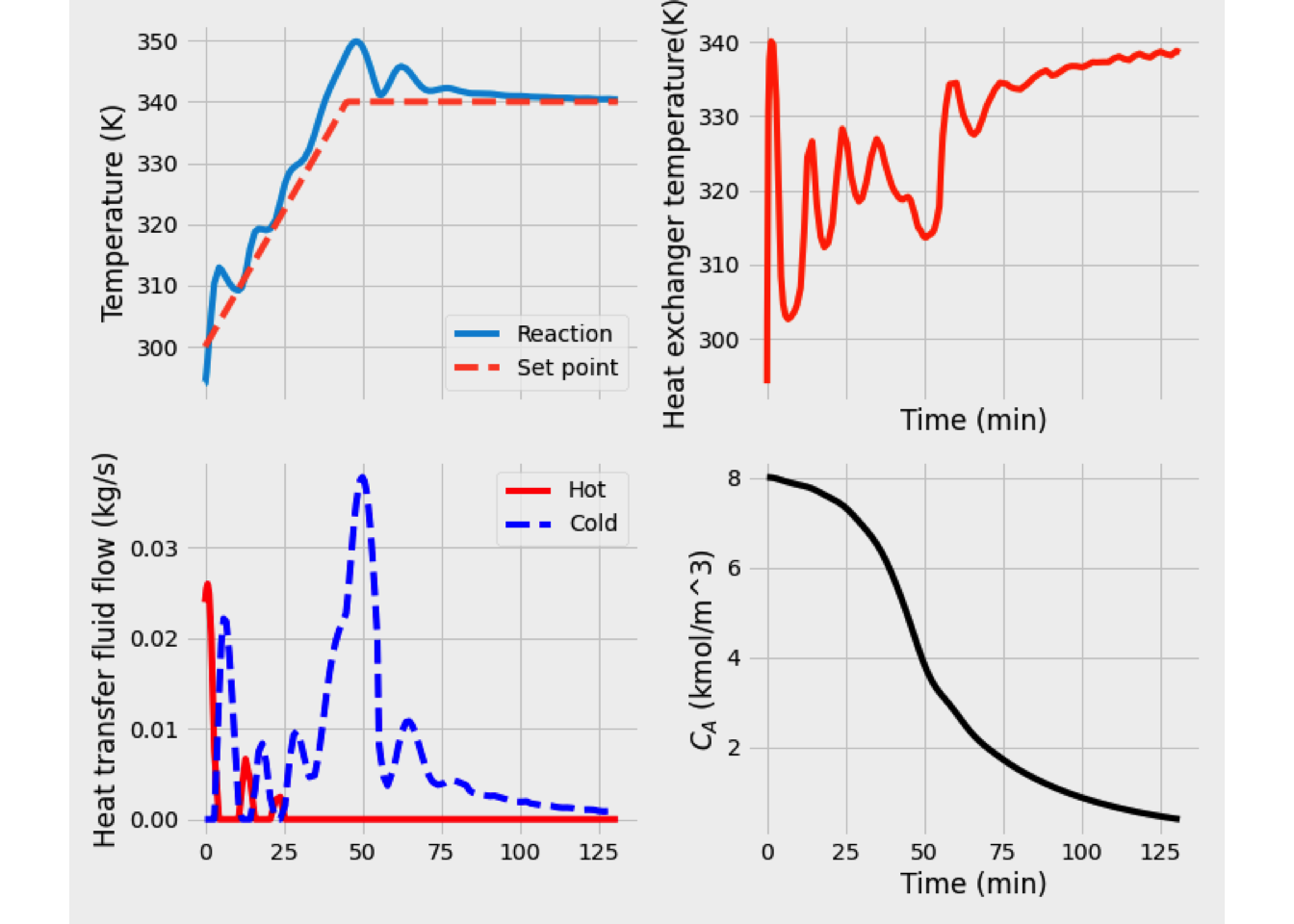

The typical reactor design situation is given the feed conditions, the kinetic information, and the desired conversion. The problem is to determine the temperature and the size of the reactor. The next illustrations show how the principles described above are applied in the design of a CSTR. See Exercise 2.1

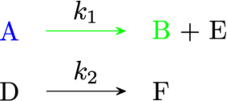

Exercise 2.1 (Operation of a cooled exothermic CSTR) An irreversible exothermic reaction is carried out in a CSTR. \[A \xrightarrow{k} {B}\]

The reaction is first-order in reactant \(A\) and has a heat reaction given by \(\Delta H_R\) which is based on reactant \(A\). Negligible heat losses and constant densities can be assumed. A well-mixed cooling jacket surrounds the reactor to remove the heat of reaction. Cooling water is added to the jacket at a rate of \(F_J\) and at an inlet temperature of \(T_{J0}\).

The volume \(V\) of the contents of the reactor and the volume \(V_J\) of water in the jacket are both constant. The reaction rate constant changes as function of the temperature according to the equation. \[\begin{equation*} k = k_0\,\exp\left( -E/R\,T\right) \end{equation*}\] The feed flow rate \(F_0\) and the cooling water flow rate \(F_J\) are constant. The jacket water is assumed to be completely mixed. Heat transfer from the reactor to the jacket can be calculated from: \[\begin{equation*} Q = U\,A_J\left(T_J - T \right) \end{equation*}\] where \(Q\) is the heat transfer rate, \(U\) is the overall heat transfer coefficient, and \(A_J\) is the heat transfer area.

- Formulate the material and energy balances that apply to the CSTR and the cooling jacket.

- Calculate the steady-state value of \(C_A\), \(T_J\), and \(T\) for the operating conditions.

- Identify all possible steady-state operating conditions, as this system may exhibit multiples steady states.

- Solve the unsteady-state material and energy balances to identify if any of the possible multiple steady states are unstable.

Solution

There are three balance equations that can be written for the reactor (respect to reactant \(A\)) and the cooling jacket.2.1 \[\begin{gather*} F_{0}C_{A0} - F\,C_A - k\,C_A\,V = 0 \\ \rho\,C_P\left(F_0\,T_0 - F\,T\right) - \Delta H_R(T)\,V\,k\,C_A + U\,A_J\left(T_J - T \right) = 0 \\ \rho_J\,C_{P_J}F_J\left(T_{J_0} - T_J \right) - U\,A_J\left(T_J-T\right) = 0 \end{gather*}\]

The operation conditions for the reactor are:

| Sym | Value | Sym | Value |

|---|---|---|---|

| \(F_0\) | 40 ft\(^3\)/h | \(U\) | 150 btu/h-ft\(^2\)-R |

| \(F\) | 40 ft\(^3\)/h | \(A_J\) | 250 ft\(^2\) |

| \(C_{A0}\) | 0.55 lbmol/ft\(^3\) | \(T_{J0}\) | 530 R |

| \(V\) | 48 ft\(^3\) | \(T_{0}\) | 530 R |

| \(F_J\) | 49.9 ft\(^3\)/h | \(\Delta H_R\) | \(-30\,000\) btu/lbmol |

| \(C_P\) | 0.75 btu/lb-R | \(C_{P_J}\) | 1 btu/lb-R |

| \(k_0\) | 7.08E10 h\(^{-1}\) | \(E\) | \(30\,000\) btu/lbmol |

| \(\rho\) | 50 lb/ft\(^3\) | \(\rho_J\) | \(62.3\) lb/ft\(^3\) |

| \(R\) | 1.9872 btu/lbmol-R |

All these values were implemented into modeling equations into a Python script link. The solution obtained was:

| Variable | Value |

|---|---|

| \(C_A\) (lbmol/ft\(^3\)) | 0.521 |

| \(T\) (R) | 537.25 |

| \(T_{J}\) (R) | 537.25 |

When we are dealing with exothermic reactions, several steady states may be possible in a CSTR, which can easily calculate them if we rewrite the equations like so:

\[\begin{align*} C_A &= \frac{F_0\,C_{A0}}{F+V\,k} \\ T_J &= \frac{\rho_J\,C_{P_J}F_J\,T_{J_0} + U\,A_J\,T}{\rho_J\,C_{P_J}\,F_J+ U\,A_J} \end{align*}\]

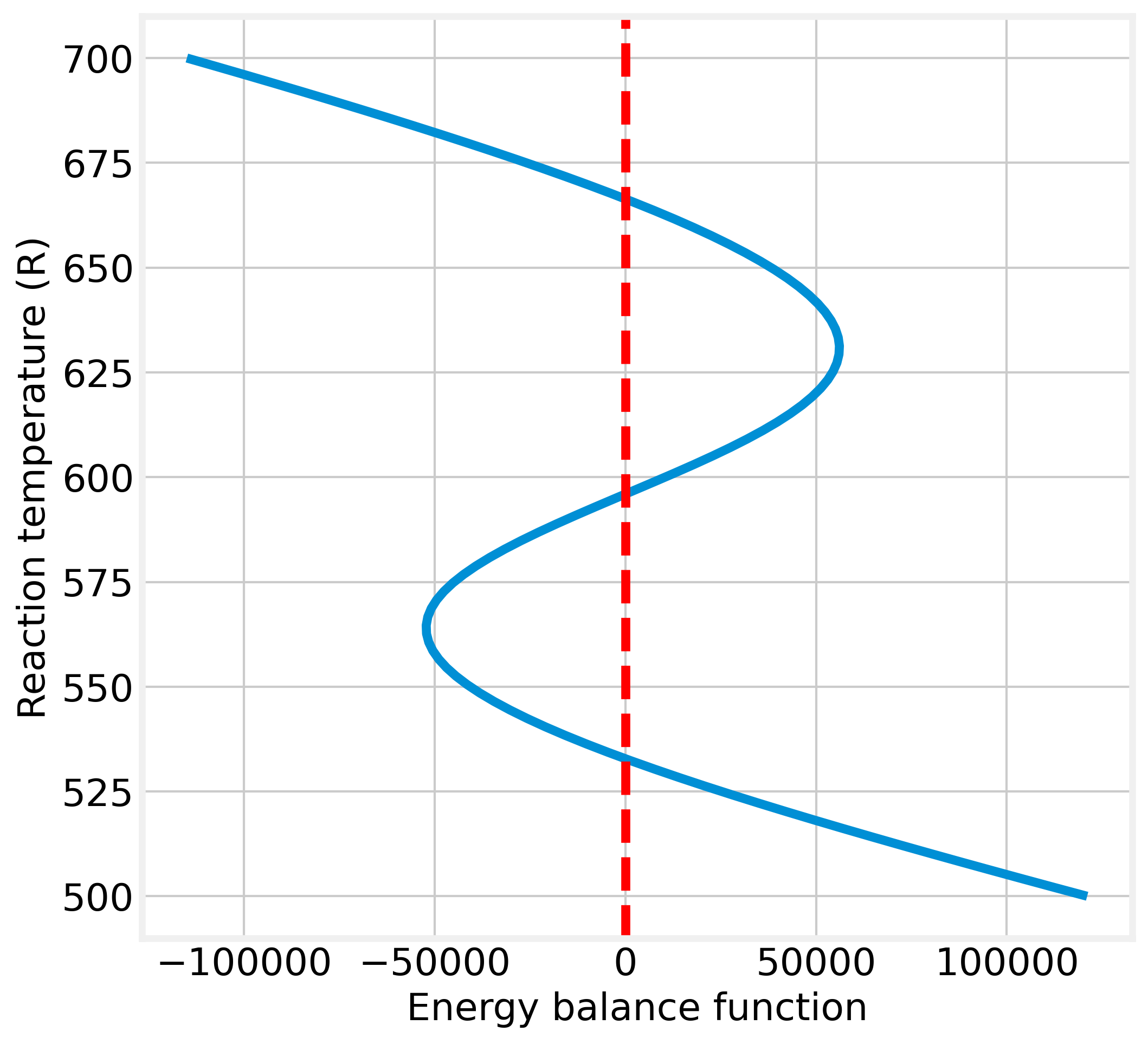

Now, these equations are solved for a range \(500 \leq T \leq 700\), next their results are evaluated into energy balance function (eq. @ref{eq:ec003020b}) on the reactor.

\[\begin{equation} f(T) = \rho\,C_P\left(F_0\,T_0 - F\,T\right) - \Delta H_R(T)\,V\,k\,C_A + U\,A_J\left(T_J - T \right) \tag{2.33} \end{equation}\]

These equations are solved for a range from 500 to 700. Next, their results are evaluated into energy balance function on the reactor. The results obtained are plotted vs \(T_R\) in figure 2.12.

Figure 2.12: Graphical indication of multiple steady-states solutions

Figure 2.12 shows the system has three operating-points. Now, how a CSTR can operate at multiple steady-states is necessary to know which is (or which of them) stable for the operating condition. Thus, the next step in designing a non-isothermal CSTR must be to carry out a steady-state analysis.

Usually, the stability analysis can be done from the plot HPR(T)-HWR(T) vs. reaction temperature.

Figure 2.13: Graphical solutions of the heat balance for a CSTR

Figure 2.13 shows HPR is a sigmoidal curve because of the rate constant’s exponential temperature dependence. The shape of the curve depends in large part on the value of the activation energy.

All possible reactor operating temperatures must satisfy both functions, HPR and HWR, such that the two functions have equal values. These operating points are represented in Fig. 2.13 by circles.

Additionally, Figure 2.13 shows that the HWR line intercepts the HPR curve in three points at the same temperatures shown in Figure 2.12. Gray dots represent stable conditions, and especially the latter point is of practical interest since it represents a high degree of conversion.

The stable conditions are related to the fact that the heat removal line’s slope should be greater than that of the heat production line. Under that condition, more heat is removed on a positive deviation from the operating point than produced heat so that the reaction temperature will return to the steady-state value.

Figure 2.13’s black circle is an unstable operating condition because the situation is reversed than for gray dots. Since the heat production curve slope is here more significant than that of the heat removal line, any positive temperature deviation will be amplified until the reactor works in the upper stable operating point and vice versa.

In summary, the lower stable steady-state operating point in Figure 2.12 corresponds to low rates of heat generation and removal. This combination may result from one or more of the following factors:

- Small values of \(\Delta H_R\);

- Low value of the reaction rate constant;

- Short average residence time;

- Small value of the feed rate, and

- Fast removal of heat from the reactor, which does not cause the temperature to rise to higher values.

On the other hand, the higher stable steady-state operating point in Figure 2.12 corresponds to the reactant’s nearly complete consumption. This outcome is favored by:

- An enormous value of \(\Delta H_R\);

- A more considerable value of the reaction rate constant;

- Longer average residence time;

- Larger reactant throughput, and

- A slower heat removal regime by a heat exchanger.

Whether the reactor operates at a lower or higher stable point depends on how it is started up. The unsteady energy and material balances must be solved simultaneously to determine the effect of startup conditions.

The type of stability analysis carried out above is not mathematically rigorous. However, it is a handy way to understand the concept of stable and unstable operating points. In mathematical terms, the above analysis has shown that a steady-state operating will be unstable if \[\begin{equation*} \left[\frac{\partial HPR(T)}{\partial T}\right]_\text{operating point} > \left[\frac{\partial HWR(T)}{\partial T}\right]_\text{operating point} \end{equation*}\]

and will be stable if \[\begin{equation*} \left[\frac{\partial HPR(T)}{\partial T}\right]_\text{operating point} < \left[\frac{\partial HWR(T)}{\partial T}\right]_\text{operating point} \end{equation*}\]

The first inequality is a sufficient criterion for instability so that the operating point will be intrinsically unstable in this situation. The second inequality is a sufficient criterion for stability, provided that the CSTR is adiabatic. If the reactor is not adiabatic, the second condition is necessary but not sufficient.

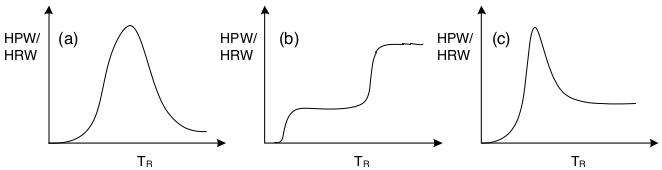

It is important to remark that the curve HPR/HRW vs. T performed in Fig. 2.12 corresponds to a simple reaction rate expression \(r_A = - k\,C_A\). As the reaction change’s characteristics, the shape of that curve will change, and the resulting analysis will need to be accordingly modified.

Figure 2.14 presents qualitative forms of the HPW/HWR curve for (a) a reversible reaction, (b) a pair of consecutive exothermic reactions, and (c) for two consecutive reactions, where the first is exothermic and the second is endothermic.

Figure 2.14: Qualitative shape of HPR/HPWR curve for several kind of reactions

Internal Coil

If an internal coil is used, the cooling medium flows in plug flow through the coil. The temperature differential driving force for heat transfer is a log mean average of the differential temperatures at the coil’s two ends.

\[\begin{gather} \Delta T_\text{in} = T_R - T_{C,\text{in}} \notag \\ \Delta T_\text{out} = T_R - T_{C,\text{out}} \\ {\left(\Delta T\right)}_{LM} = \cfrac{\Delta T_\text{in} - \Delta T_\text{out}}{\ln\left(\cfrac{\Delta T_\text{in}}{\Delta T_\text{out}}\right)} \notag \tag{2.34} \end{gather}\] where: \(T_{C,\text{in}}\) is the supply temperature of cooling medium (K) and \(T_{C,\text{out}}\) is the temperature of cooling medium leaving the coil (K).

The energy balance on the coil is again given by the eq. (2.32). While the heat transfer rate is given by \[\begin{equation} Q_\text{coil} = U\,A_\text{coil}\Delta T_{LM} \tag{2.35} \end{equation}\] There are several issues to be resolved in the design of a cooling coil but these will not be considered for this course.

Exercise 2.2 (Non-rigorous coil design for a CSTR) As illustration, let us design (non-rigorous) a coil heat exchanger for a CSTR presented in part 1 of the illustration 2.1. The following coil specification are used in this illustration:

- the pipe diameter is 5/8 in.

- the loop diameter constitutes 80% of the diameter of the vessel.

- The spacing between the loop flights is the diameter of the pipe.

- Only one coil is used.

- The reactor vessel has an aspect ratio (L/D) of 2.

Solution. In order to solve this problem, it is required two iterative calculations. One to determine the size of the reactor, including the coil heat exchanger, and the second one to determine the coolant flow rate required

In the first iterative calculation, it must include following equations:

\[\begin{align*}

&\text{Length of the reactor} && L_R = 2\,D_R \\

&\text{Number of coils} && N = \frac{L_R}{2D_\text{coil}}\\

&\text{Length of coil} && L_\text{coil} = 0.8\,D_R\,\pi\,N \\

&\text{Volume of coil} && V_\text{coil} = \frac{\pi D_\text{coil}^2}{4}\,L_\text{coil}

\end{align*}\]

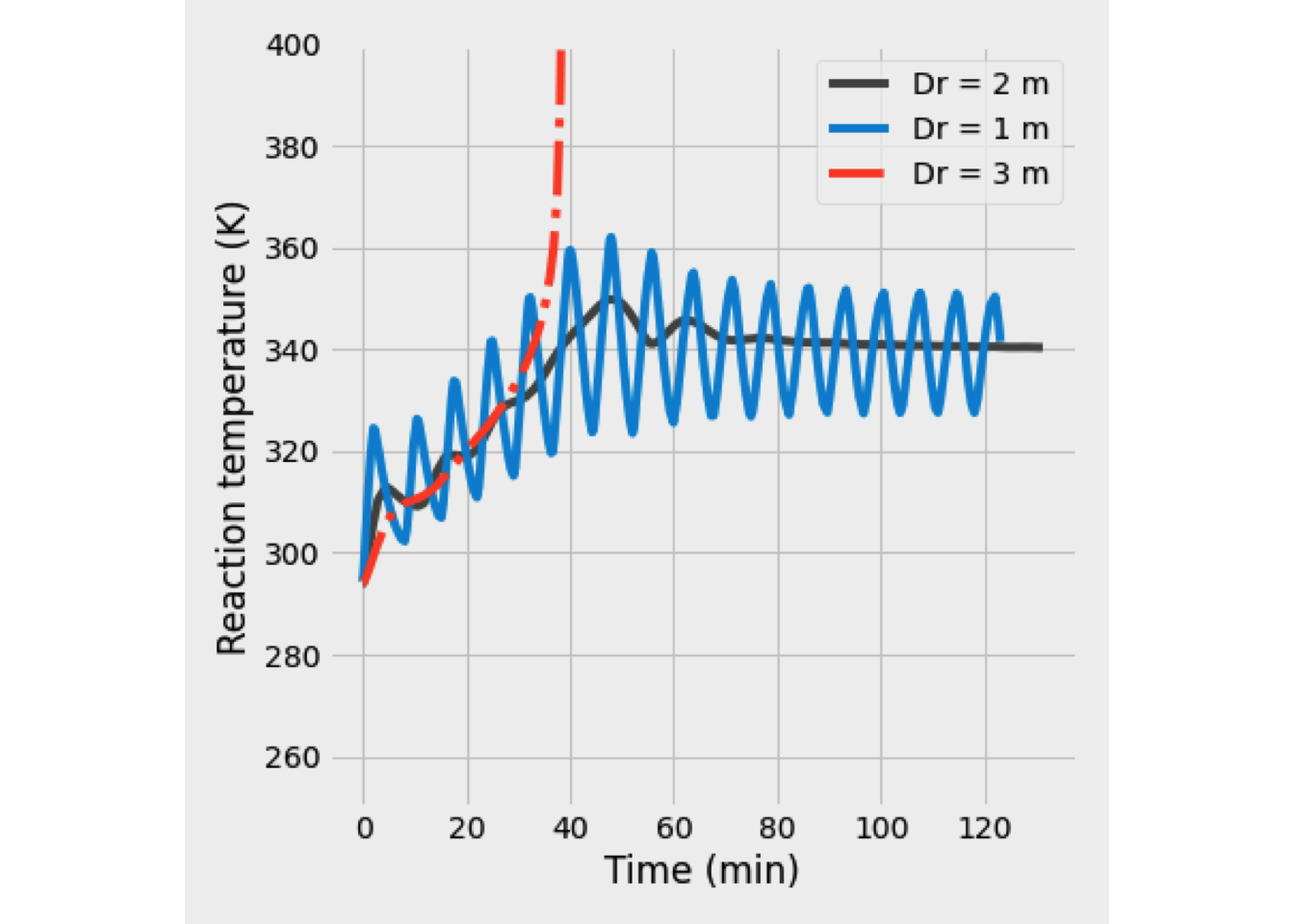

This problem was implemented in Python and the results obtained were:

Reactor size parameters including coil heat exchanger:

Reactor diameter: 1.55 m

Reactor volume: 6.0 m

Coil heat exchanger parameters:

Transfer area: 19.09 m\(^2\)

Number of loops: 98

Coil volume: 0.08 m\(^3\)

Coil length: 382.87 m

Cooling fluid parameters:

Exit temperature: 436.15 K

Log-mean temperature difference: 7.10 K

Coolant flowrate: 34.88 cm\(^3\)/s

The main advantage of a coil over a jacket is more transfer area.

Reactors in series

In the general energy balance (eq. (2.4)), the extent of reaction, \(\xi_j\), in the inlet stream was taken to be zero. When dealing with CSTRs in series, this balance must include the change in extension of reaction or fractional conversion per each CSRT referred to in the first reactor. (Roberts 2009)

Then, if only one reaction is taking place, the Eq. (2.4) becomes \[\begin{equation} Q - \left(\sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{C}_{p,i}\right) \left(T_{\text{out}} - T_{\text{in}}\right) - F_{A0}\left(X_{A,out} - X_{A,in} \right)\Delta H_{R}(T) = 0 \tag{2.36} \end{equation}\]

If more than one reaction occurs, and if the extents of reaction in the feed to a reactor or segment are denoted \(\xi_k^0\), then eq. (2.4) becomes

\[\begin{equation} \frac{dU}{dt}= Q - \left(\sum\limits_{i=1}^{\mathcal{C}} F_{i0}\,\overline{C}_{p,i}\right)\left(T_\text{out} - T_\text{in}\right) - {\sum_{j=1}^R} \left(\xi_j - \xi_j^0\right) \,\Delta H_{R,j}(T) \tag{2.37} \end{equation}\]

It is essential to point out that in Eqs. (2.36) and (2.37), Q is the rate at which heat is transferred into the reactor section under consideration, i.e., for which the inlet temperature is \(T_\text{in}\), and the outlet temperature is \(T_\text{out}\).

Finally, it is necessary, the temperature correction for the heat of reactions is based on: \[\begin{equation*} \Delta H_{R,j}(T) = \Delta H^\circ_R(T^\circ) + \int_{T^\circ}^T \sum\nu_i C_{p,i}\,dT \end{equation*}\]

where \(\Delta H^\circ_R(T^\circ)\) is usually calculated from enthalpies of the formation of components involved in the chemical reaction.

Exercise 2.3 (Heat transfer requirement for multiple CSTRs) Reactant A undergoes an essentially irreversible isomerization reaction that obeys first-order kinetics. An irreversible exothermic reaction \[\begin{equation*} A \rightarrow B \end{equation*}\]

Both A and B are liquids at room temperature ad both have too high boiling points. Consider the possibility of using one or more CSTRs operating in series. If each CSTR operates at 163C and if the feed stream consists of pure A entering at 20C.

Determine the reactor volumes and heat transfer requirements to produce 2 million pounds in 7000 h for

- A single CSTR.

- Three identical CSTRs in series.

Data and assumptions

- Reaction rate expression: \(r = k\,C_A\).

- Rate constant at 163C = 0.8 h-1.

- Heat of reaction = -83 cal/g.

- Molecular weight = 250.

The heat capacities of species A and B may be assumed to be identical and equal to 0.5 cal/g-C. Their densities may be assumed to be equal to 0.9 g/cm3. The conversion final is 97%

Solution

1. For a CSTR. From the CSTR’s design equation

\[\begin{equation*}

{C_A}={\frac {{C_{A0}}}{1+k\tau}}

\end{equation*}\]

Additionally, \[\begin{equation*} {X_A}={1-\frac{C_A}{C_{A0}}} \end{equation*}\]

So, combining two last equations with \(k\) and \(X_A\) values \[\begin{equation*} 0.97=-\frac{1}{1+ 0.8\,\tau}+1 \Rightarrow \tau = 40.42 \;\text{h} \end{equation*}\]

From problem data given: \[\begin{align*} F_{A0} &= 1.297\cdot 10^5 \;\frac{\text{g}}{\text{h}} \\ \upsilon &= 144.13 \;\frac{\text{L}}{\text{h}} \\ \mathbf{ V_R} &= \mathbf{5825.13} \;\textbf{L} \end{align*}\]

The \(Q\) is calculated from Eq. (2.27) \[\begin{equation*} \mathbf{Q} = - \,1.1687 \cdot 10^6 \;\frac{\text{cal}}{\text{h}} = \mathbf{-\,4634.85} \;\frac{\textbf{btu}}{\textbf{h}} \end{equation*}\]

- For a three-CSTR series For the last reactor, \[\begin{equation*} C_{A3}=\frac{C_{A0}}{{\left( 1+k\tau \right)}^{3}} \end{equation*}\]

This equation could be rewritten in \[\begin{equation*} X_{A3} =- {\left( 1+k\tau \right)}^{-3}+1 \end{equation*}\] Thus, \(\boldsymbol{\tau} = \mathbf{2.77}\) h, therefore \(\mathbf{V_R = 399.645}\) L

The heat requirement for each reactor is calculated from \(\tau\) and the fractional conversion reached in each of them. Thus, \[\begin{align*} C_{A1}&=\frac{C_{A0}}{1+k\tau} \Rightarrow &&\mathbf{X_{A1} = 0.689} &&\\ C_{A2}&=\frac{C_{A0}}{{\left(1+k\tau\right)}^2} \Rightarrow && \mathbf{X_{A2} = 0.9034}&& \end{align*}\]

Finally, \[\begin{align*} \mathbf{Q_1} &= \left( F_{A0} \int\limits_{20}^{163} C_P\,dT + F_{A0} \,X_{A1} \,\Delta H_R\right) \frac{1}{252.16} = \mathbf{7350.97} \;\frac{\textbf{btu}}{\textbf{h}} \\ \mathbf{Q_2} &= \left(F_{A0} \left[X_{A2} -X_{A1}\right]\Delta H_R\right) \frac{1}{252.16} = \mathbf{-\,9144.44} \;\frac{\textbf{btu}}{\textbf{h}} \\ \mathbf{Q_3} &= \left(F_{A0} \left[X_{A3} -X_{A2}\right]\Delta H_R\right) \frac{1}{252.16} = \mathbf{-\,2841.39} \;\frac{\textbf{btu}}{\textbf{h}} \end{align*}\]

2.3 Plug-flow reactor (PFR)

Plug flow is a simplified and idealized picture of a fluid’s motion, whereby all the fluid elements move with a uniform velocity along parallel streamlines. This perfectly ordered flow is the only transport mechanism accounted for in the plug flow reactor model.

In summary, the essential features of a PFR are:

- The volumetric flow may vary continuously in the direction of the flow because of a change in density,

- Each element of fluid is a closed system; that is, there is no axial mixing (it seems a CSTR),

- fluid properties may change continuously in the axial direction but are constant radially at a given axial position,

- Each element of fluid has the same residence time, t, as any other.

This kind of reactor is usually used:

- When a high flow rate of the reacting system is needed (fast reactions).

- Large scale.

- High temperature.

- Homogeneous or heterogeneous reactions.

- Continuous operations.

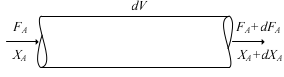

In a PFR, the composition of the fluid varies from point to point along a flow path. Thus the material balance for a reaction component must be made for a differential element dV, as shown in Figure 2.15.

Figure 2.15: Plug-flow reactor volume element

Under steady-state operation, the material balance is expressed in terms of the molar flow. \[\begin{equation} dV = \frac{dF_A}{r_A} \tag{2.38} \end{equation}\] Equation (2.38) is the design equation for an ideal PFR.

For a single reaction, it may be convenient to write Eq. (2.38) in terms of fractional conversion of a key reactant \[\begin{align} F_A =& F_{A0}\left(1-X_A\right) \\ dF_A =& - F_{A0}\,d X_A \\ \frac{dV}{F_{A0}} =& - \frac{dX_A}{r_A} \tag{2.39} \end{align}\]

The equation (2.39) could be rewritten as a differential equation representing the gradient of \(X_A\) for a position (z) in a PFR. Assuming that the reactor is a cylinder of radius R. The volume of the reactor from the inlet to position is \(V(z) = \pi R^2 z\), so: \[\begin{equation} \frac{dX_A}{dz} = - \frac{\pi\,R^2\,r_A}{F_{A0}} \tag{2.40} \end{equation}\]

Under the traditional approach for sizing reactors, the equation (2.39) is rewritten depending on the reacting fluid density. As far as I understand, it is unnecessary because of software like Python or Matlab, making more straighforward numerical calculations. Despite that, let us study how the equation design changes on a constant- and variable- density fluid.

2.3.1 Design equation

Constant-Density System

If the reacting fluid keeps its density constant during the chemical reaction, then Equation (2.39) can be written in terms of the initial concentration of limiting reactant (\(C_{A0}\)) and the spacial time (\(\tau\)) \[\begin{equation} d\,\tau = - C_{A0}\frac{dX_A}{r_A} \equiv \frac{dC_A}{r_A} \tag{2.41} \end{equation}\]

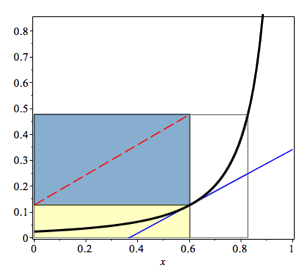

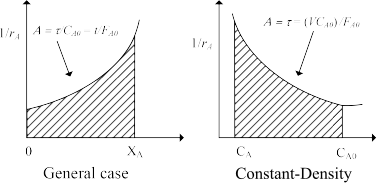

A graphical interpretation of equations (2.39) and (2.41) is illustrated in Figure 2.16

Figure 2.16: Graphical interpretation of design equation for a PFR

The shape of figure 2.16 is based on the assumption that \(-r_A\) decreases as \(X_A\) increases. Thus equation (2.39) states that \((V/F_{A0})\) for an ideal PFR is the area under the curve of \((1/-r_A)\) vs. \(X_A\), between the inlet and outlet fractional conversion.

Variable-Density System

When the reacting system’s density is not constant throughout a PFR, the size of a PFR must be calculated using the general design equation (Eq. (2.39)).

For example for an irreversible first-order reaction, which \(r_A = - k\,C_A\). The kinetic equation will be written as \[\begin{equation*} r_A = - k\,C_A = -k\,\frac{F_A}{\upsilon} = - k\,F_{A0}\:\frac{\left(1-X_A\right)}{\upsilon} \end{equation*}\]

Thus, the equation design is \[\begin{equation} \tau = - C_{A0} \int_0^{X_A} \frac{d\,X_A}{r_A} = C_{A0} \int_0^{X_A} \frac{\upsilon\:d\,X_A}{k\:F_{A0}\:\left(1-X_A\right)} = \frac{1}{k\:\upsilon_0} \int_0^{X_A} \frac{\upsilon\:d\,X_A}{1-X_A} \tag{2.42} \end{equation}\]

Taking into account that, in this case, \(\upsilon = \upsilon_0 \left(1 + \varepsilon_A\,X_A\right)\) then (2.42) becomes \[\begin{equation} \tau = \frac{1}{k} \int_0^{X_A} \frac{\left(1 + \varepsilon_A X_A\right)}{1-X_A}\:dX_A \tag{2.43} \end{equation}\]

As it was mentioned before, for ideal PFR, all fluid elements take the same length of time in the reactor. This time is called mean residence time (\(\overline t\)) and, in general, it could be calculated by: \[\begin{equation} \overline{t} = \int_{0}^{V} \frac{dV}{\upsilon} \tag{2.44} \end{equation}\] where \(\upsilon\) is the volumetric flow rate.

The space-time and the mean residence time are identical when there is no density change in the reactor. For analyzing kinetic data obtained from tubular reactors, the \(\tau\) is a more useful variable than t because the former is an independent variable. In contrast, the latter only can be obtained if the progressive changes occurring within the reactor are known beforehand.

For systems of constant density, the performance equations are identical for a BR and PFR, which means \(\tau\) for PFR is equivalent to \(t\) for the BR

To demonstrate how to use the expressions for PFR, let us solve the next problem.

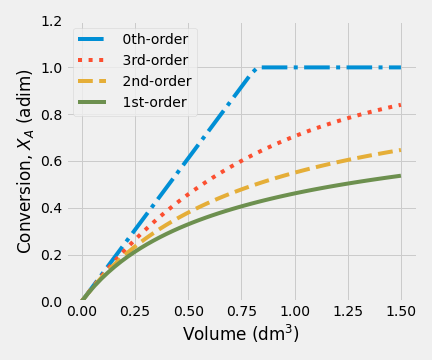

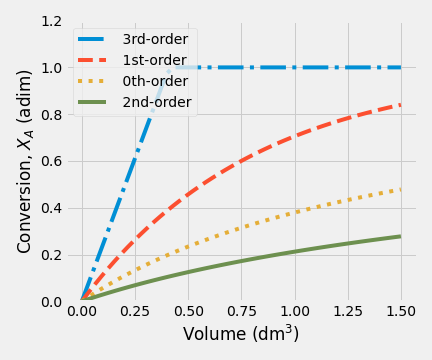

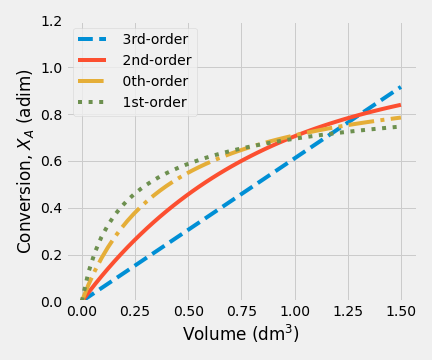

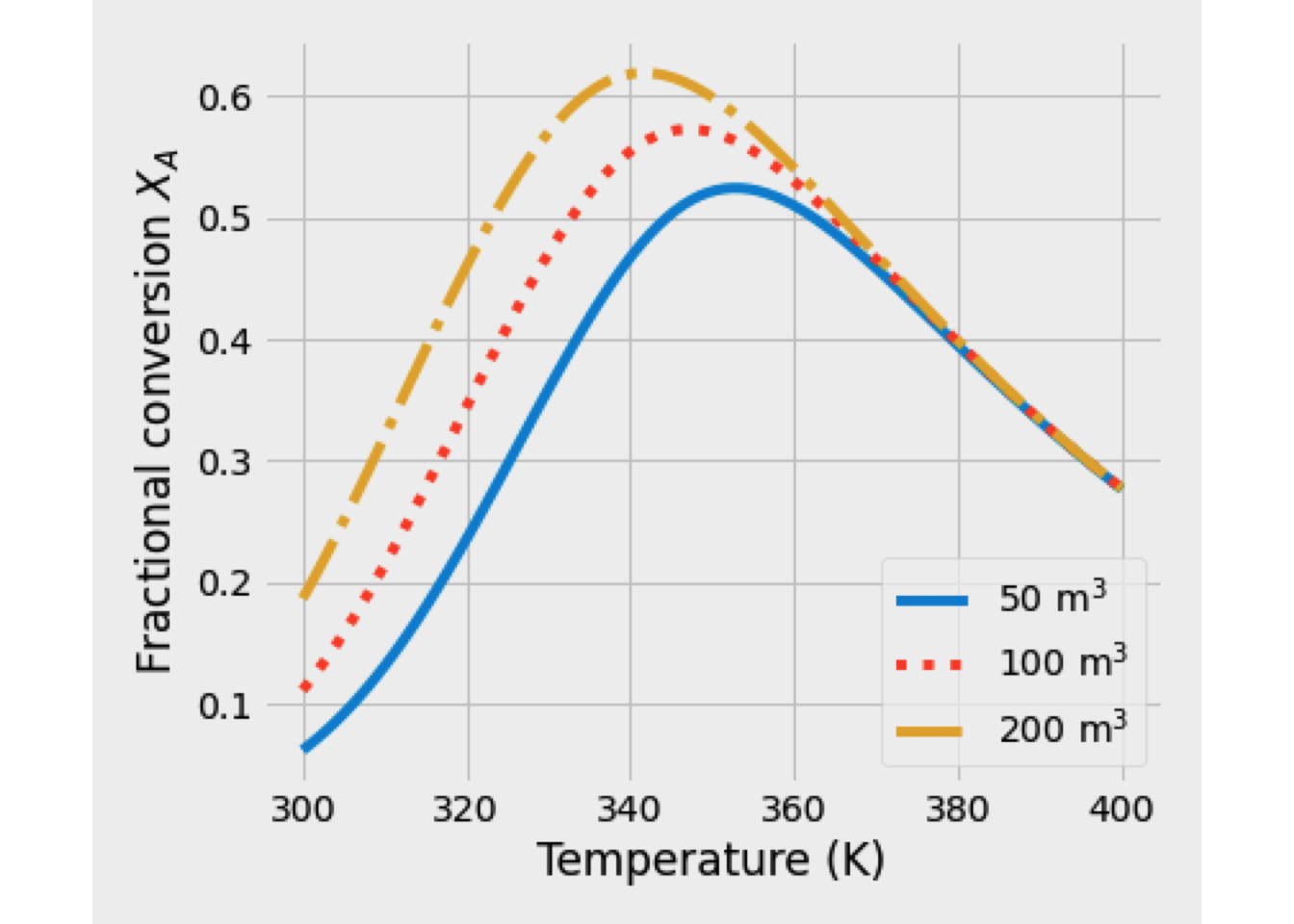

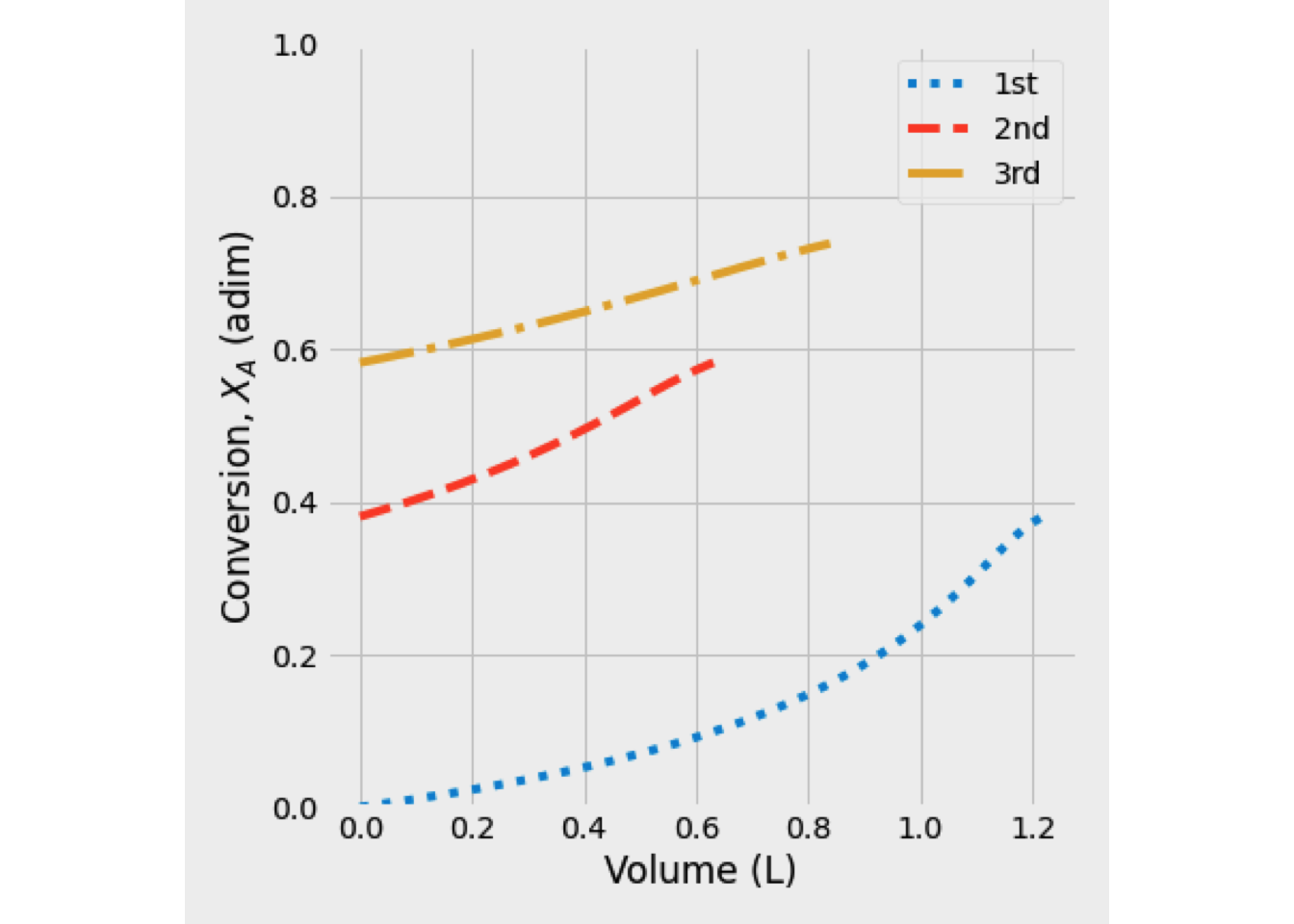

Exercise 2.4 (Effect of the rate laws over PFR performance) Consider the effect of reaction on conversion in a PFR whose volume is \(1.5\) dm\(^3\). The irreversible liquid phase reaction \(A \rightarrow B\) is taking place in which the feed concentration is \(C_{A0} = 1.0\) mol/dm\(^3\) and the volumetric flow rate is \(\upsilon_0 = 0.9\) dm\(^3\)/min. The reaction rate constant for various reaction orders is fixed at 1.1 for this comparison with units consistent with the concentration mentioned above and flow rate.

- Plot the conversion in a PFR as a function of reactor volume for zero-, first-, second-, and third-order reaction to a reactor volume of \(1.5\) dm\(^3\).

- Repeat for feed concentrations of \(C_{A0}\) at 0.5 and 2.0 mol/dm\(^3\).

Solution. For the PFR, a differential mole balance gives the following differential equation for converting A \[\begin{equation} \frac{dX}{dV} = - \frac{r_A}{F_{A0}} \tag{2.45} \end{equation}\]

where the rate law is \[\begin{equation*} r_A = - k\,{C_{A}}^n \end{equation*}\] and n = 0, 1, 2, or 3 according to the reaction’s order. As an initial condition for eq. (2.45) is that there is no conversion at the reactor inlet. Additionally, if constant temperature and pressure are considered, then the concentration of reactant A could be expressed using conversion as: \[\begin{equation*} C_A = C_{A0} \left( 1 - X_A \right) \end{equation*}\]

Part 1 of this problem was solved in Python, and the graphical results are given

Figure 2.17: Fractional conversion vs volume for various reaction orders

Figure 2.17 shows clearly the effect of reaction on conversion in a PFR, for zero-order kinetic will obtain higher conversion than other cases. As we expect, for a zero-order kinetic, fractional conversion shows an independent behavior of concentration A. That is why a linear function is observed when the fractional conversion is less than one.

In those cases, when order-kinetic is more significant than zero, fractional conversion shows an exponential behavior, and the final conversion value decreases inversely to order-kinetic.

The results for item 2 were plotted. When the initial concentration of A decreases to 0.5 mol/dm\(^3\), fractional conversion changes in the same way. The main difference with item 1 is that final conversion values, for order-kinetic greater than zero, are less.

The results obtained when the initial concentration of A was increased to 2.0 mol/dm\(^3\) are shown.

| (a) \(C_{A0} = 0.5\) mol/dm\(^3\) | (b) \(C_{A0} = 2.0\) mol/dm\(^3\) |

|---|---|

|

|

2.3.2 Energy balance

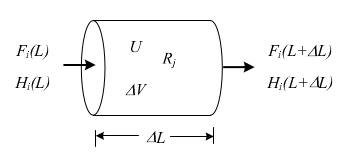

This section will derive an energy balance for a PFR, considering the volume element in Figure 2.18. Additionally, it will be assumed temperature and composition of the reaction mixture are uniform over the cross-section of the PFR and depend only on the distance L from the feed point.

Figure 2.18: PFR reactor volume element

According to Fig. 2.18, the steady-state energy balance over a differential volume of the reactor becomes, if any work done by the reaction mixture is neglected: \[\begin{equation} \frac{dQ}{dV} - \frac{d}{dV}\left(\sum\limits_{i=1}^{\mathcal{C}} F_{i} \, H_i \right)= 0 \tag{2.46} \end{equation}\]

The enthalpy term can be broken apart into two terms: \[\begin{equation} \frac{dQ}{dV} - \sum\limits_{i=1}^{\mathcal{C}} \left(\frac{dF_{i}}{dV} \, H_i\right) -\sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, \frac{dH_{i}}{dV} \right)= 0 \tag{2.47} \end{equation}\]

The differential of enthalpy is \[\begin{equation} \frac{dH_i}{dV} = C_{Pi}\,\frac{dT}{dV} + \left[V_i-T\left(\frac{\partial V_i}{\partial T}\right)_P\right]\frac{dP}{dV} \tag{2.48} \end{equation}\]

If the pressure changes over enthalpy are neglected \[\begin{equation} \frac{dH_i}{dV} = C_{Pi}\,\frac{dT}{dV} \tag{2.49} \end{equation}\]

The second term in Fig. (2.46) is related to a molar balance over specie i. If we consider that only one reaction is taking place in the PFR: \[\begin{equation} \frac{dF_i}{dV} = \nu_i \, r \tag{2.50} \end{equation}\]

Substituting (2.50), (2.49) into (2.47) to give \[\begin{equation} \frac{dQ}{dV} - \sum\limits_{i=1}^{\mathcal{C}} \left(H_i\,\nu_i\right)r -\sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, C_{Pi}\right)\,\frac{dT}{dV} = 0 \tag{2.51} \end{equation}\] This equation is equivalent to: \[\begin{equation} \frac{dQ}{dV} = \Delta H_R\,r + \sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, Cp_i\right)\,\frac{dT}{dV} \tag{2.52} \end{equation}\]

Equation (2.52) provided the concentration and temperature profiles in the PFR as a function of V, solving it simultaneously with Eq. (2.50), when the rate of heat transfer to the reactor is known.

In most cases, the equation (2.52) is written in terms of 1 mole of the key reactant A. \[\begin{equation} \frac{dQ}{dV} = \sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, Cp_i\right)\,\frac{dT}{dV} - \Delta H_{R,A}\:r_A , \quad r_A = - r \tag{2.53} \end{equation}\]

Therefore, \[\begin{equation} \frac{dT}{dV} = \cfrac{\cfrac{dQ}{dV} + \Delta H_{R,A}\,r_A}{\sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, Cp_i\right)}, \quad r_A = - r \tag{2.54} \end{equation}\]

Temperature and concentration profiles as function of PFR length

In case that the tube diameter is constant, it could be useful to express Eq. (2.52) considering the differential element of length (dL() rather than the differential element of volume, dV.

The volume of the reactor is related to the axial length, L, and the vessel diameter, D. Thus, over a differential element of volume: \[\begin{equation} dV = \frac{\pi\,D^2}{4}\,dL = A_t\,dL \tag{2.55} \end{equation}\] where \(A_t\) is the cross-sectional tube area.

Substituting this relationship into Eq. (2.50), the molar-balance equation then becomes for A \[\begin{equation} \frac{dF_A}{dL} = \frac{\pi\,D^2}{4}\,r_A \tag{2.56} \end{equation}\]

or, for constant-density, considering that \(F_i = A_t\,u\,C_i\) \[\begin{equation} u \frac{d\,C_i}{dL} = \nu_i\,r \tag{2.57} \end{equation}\] where \(u\) is the linear velocity with which the fluid flows through the tube, and \(C_i\) is the concentration of the specie i.

Incorporating Eq. (2.55) into the energy balance, (2.52), gives \[\begin{equation} \frac{dQ}{dL} = \sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, C_{Pi}\right)\,\frac{dT}{dL} - \frac{\pi\,D^2}{4}\,\Delta H_{R,A}\,r_A \tag{2.58} \end{equation}\]

Now, the simultaneous solution of Eq. (2.56) and Eq. (2.58) gives the temperature and concentration profiles along the reactor’s axial length, provided that the rate of external heat transfer is known.

External Heat Transfer to PFR

In such cases, when a PFR operates with heat transfer to the surroundings to control the temperature within a specified range, it is possible to impose a constant heat flux at the reactor’s wall, which could be implemented example, electrical heating.

The rate of heat transfer depends on the local temperature difference between the fluid in the reactor and the heat transfer fluid, as follow: \[\begin{equation} \frac{dQ}{dV} = U \left( T_{\infty} - T\right) \frac{dA}{dV} \tag{2.59} \end{equation}\]

where: U is overall heat transfer coefficient, \(T_{\infty}\) is the temperature of the surrounding heat transfer fluid, T is the temperature inside of the reactor, A is the heat transfer area of the reactor upon which U is based.

A represents the heat transfer area of the external wall of the tube, thus. \[\begin{equation} d\,A = p_w \, dL \end{equation}\] \(p_w\) is the perimeter length of the tube wall. Suppose the tube is cylindrical, then \(A = \pi\,D\). Thus, for a typical PFR illustrated in Figure 2.18, with a length equals to dL \[\begin{equation} \frac{dQ}{dV} = U \left( T_{\infty} - T\right) \frac{\pi\,D\,dL}{\left(\pi D^2/4\right)dL} = U \left( T_{\infty} - T\right) \frac{4}{D} \tag{2.60} \end{equation}\]

Substituting Eq. (2.60) into Eq. (2.51) \[\begin{equation} U \left( T_{\infty} - T\right) \frac{4}{D}= \sum\limits_{i=1}^{\mathcal{C}} \left(F_i \, Cp_i\right)\,\frac{dT}{dV} - \Delta H_{R,A}\,r_A \tag{2.61} \end{equation}\]

This equation is one form of the energy balance for a PFR with external heat exchange. It is widespread to rewrite the energy balance as \[\begin{equation} \frac{dT}{dV} = \frac{1}{\sum_{i=1}^{\mathcal{C}} F_{i} \,C_{P_i}}\left({\frac{4U\left(T_{\infty}-T\right)}{D} + \Delta H_{R,A}\,r_A}\right) \tag{2.62} \end{equation}\]

Writing Eq. (2.62) in terms of the length by substituting Eq. (2.53) \[\begin{equation} \frac{dT}{dL} = \frac{1}{\sum_{i=1}^{\mathcal{C}} F_{i} \,C_{P_i}}\left(\pi\,U\,D\left(T_{\infty}-T\right) + \frac{\pi\,D^2}{4}\,\Delta H_{R,A}\,r_A\right) \tag{2.63} \end{equation}\]

Any form of energy balance equation must be combined with the molar balance over PFR to obtain the temperature and concentration profiles along the reactor. In cases in which pressure could not be neglected, the momentum balance must be added.

One standard method of reactor operation is having a phase change taking place in the heat transfer fluid, that is, a boiling or condensing fluid use. In this operating mode, \(T_\infty\) is constant, and the energy balance equation is solving based on that supposition.

Another useful assumption is considering an average heat capacity value (composition independent) which gives the following equation. \[\begin{equation*} \frac{dT}{dL} = \frac{\pi\,U\,D}{\dot{m}\,\overline{C}_P}\left(T_{\infty}-T\right) + \frac{\pi\,D^2}{4 \dot{m}\,\overline{C}_P}\Delta H_{R,A}\,r_A \end{equation*}\]

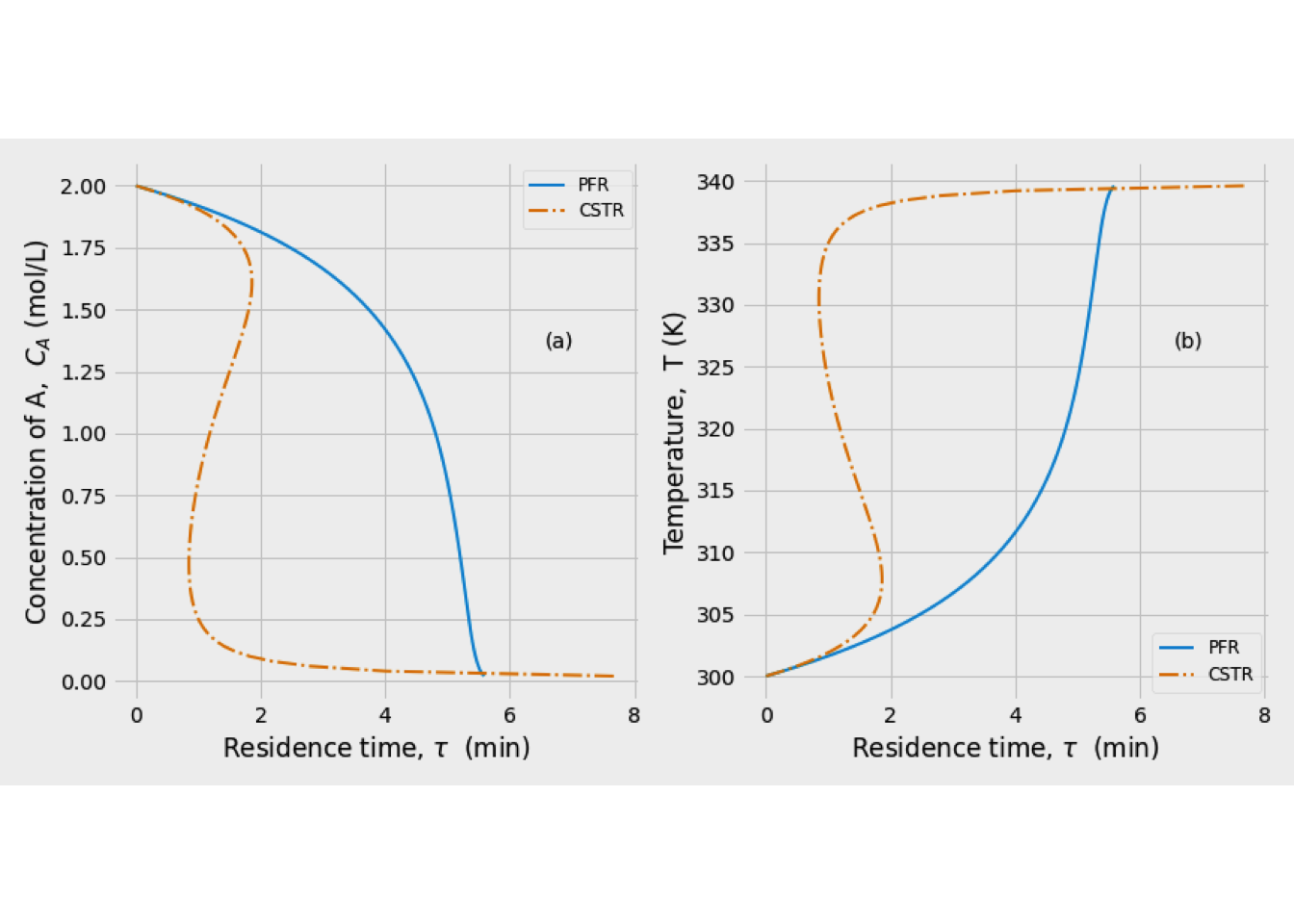

From temperature analysis, there are four essential differences between PFRs and CSTRs.

- The variation properties with axial position down the length of the reactor. In CSTR, the maximum reaction temperature is reached at the exit of the reactor under steady-state conditions. However, in a PFR, the peak temperature usually occurs at an intermediate axial position in the reactor. (assuming irreversible and exothermic reaction).

- In a CSTR, a change over an input variable has an immediate effect on variables inside the reactor. In contrast, a PFR takes time for the disturbance to work its way through the reactor to exit. Thus there are significant dynamic lags and dead time between changes made at the inlet of the reactor and temperatures and compositions further down the reactor’s length.

- It is mechanically impossible to control the reaction temperature at each axial position down the PFR. Only a single temperature can be controlled, which can be the peak temperature or exit temperature.

- In CSTR, the inlet temperature is not the most critical process variable but, in the case of a PFR, it is a design and control variable.

The primary assumption about flow pattern in a PFR is relatively reasonable for an adiabatic reactor. However, for non-adiabatic reactors, radial temperature gradients are inherent features. However, if tube diameters are kept small, the plug flow assumption is more suitable.

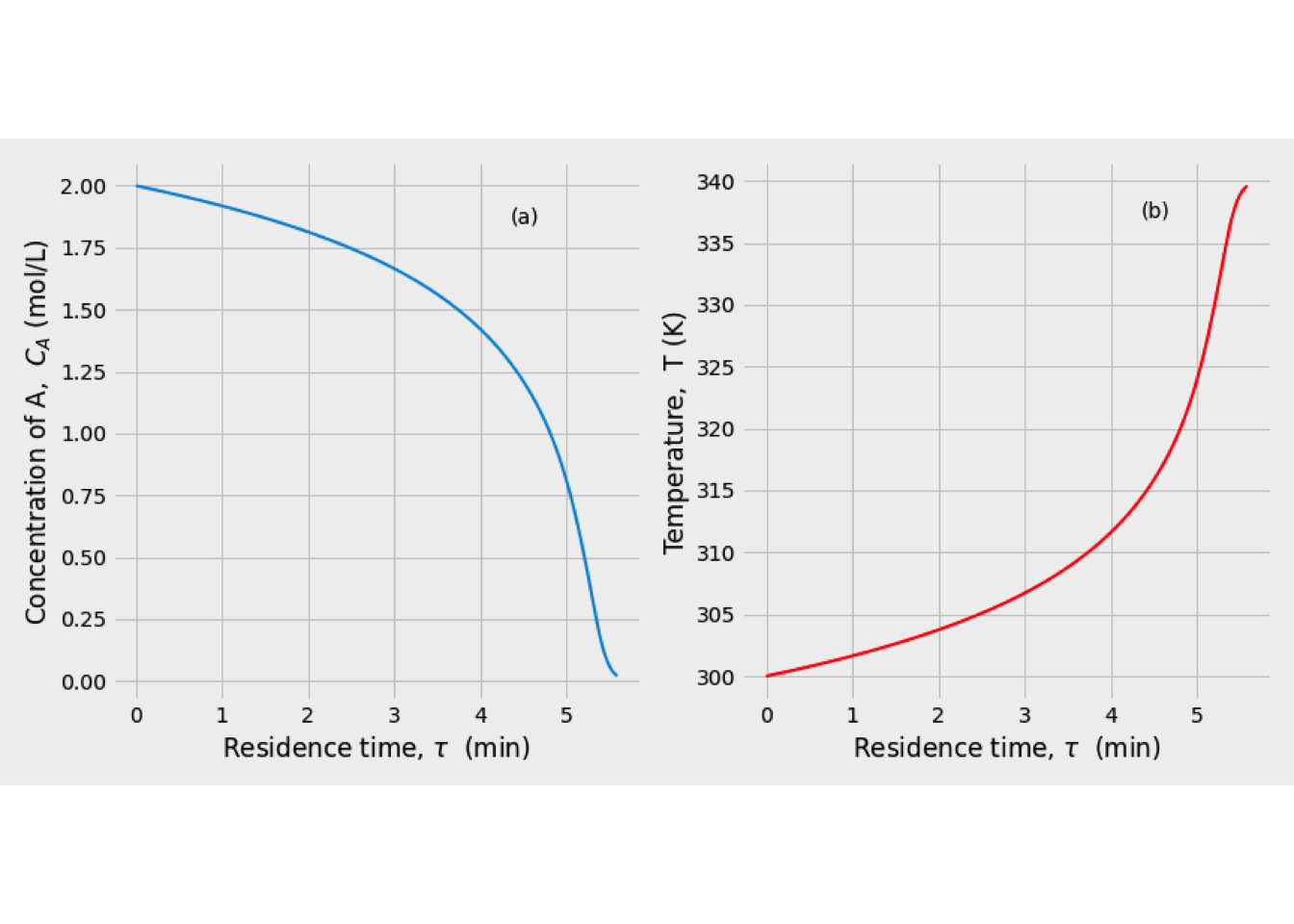

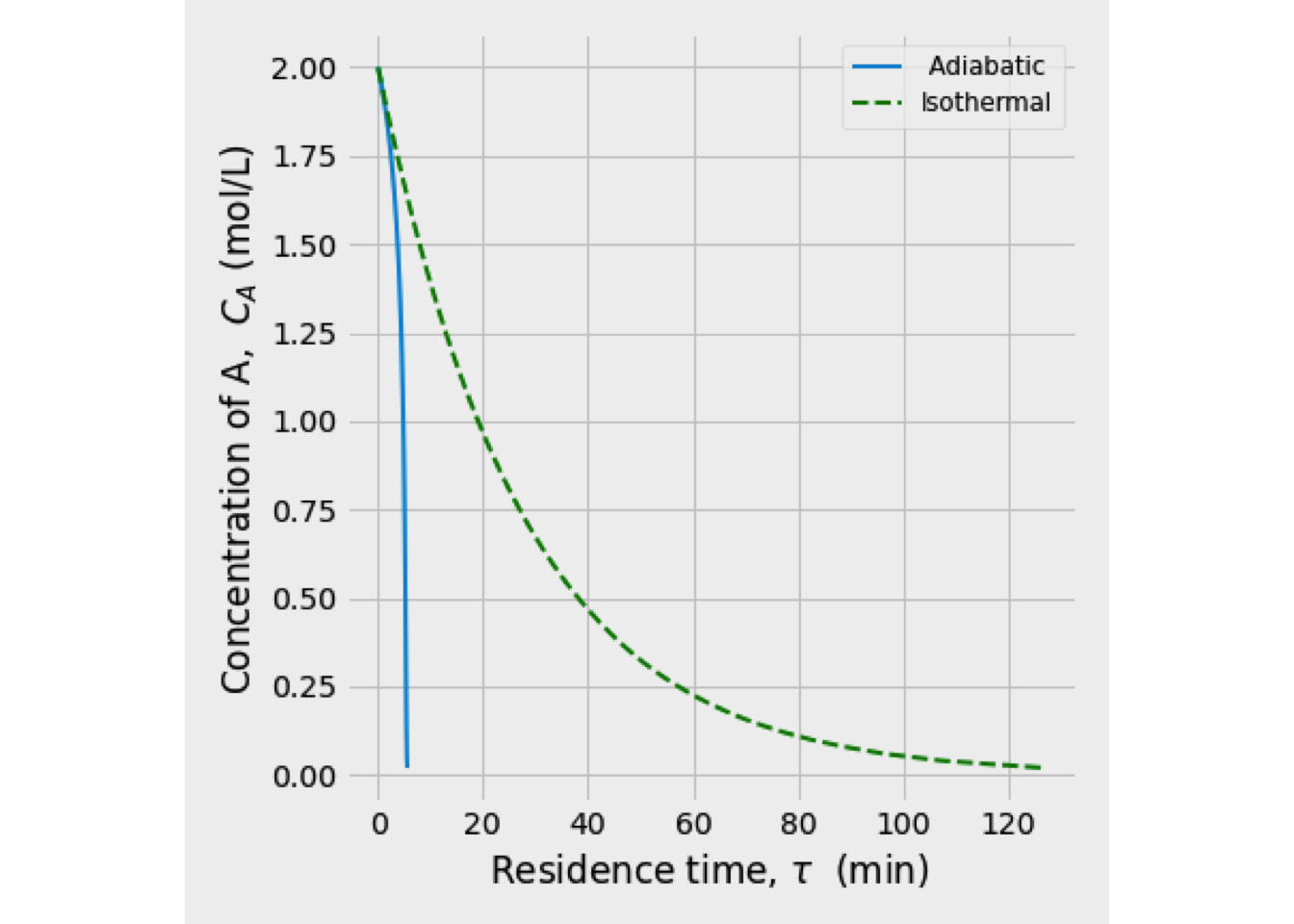

Exercise 2.5 (Heat transfer requirement for a PFR) Consider a reaction \[\begin{equation*} A \rightarrow B \end{equation*}\] Feed contains 80% \(A\) and 20% inert by weight. The molecular weight of \(A\) is 160 and that of inert is 80. The feed comes at a mass flow rate of 1 kg/s. The reaction is second order in \(A\).

Reaction data:

- The rate constant is \(k = 10^4 \exp\left(9000/T_R\right)\) m\(^3\) mol\(^{-1}\) s\(^{-1}\).

- The specific heat capacity of \(A\) and \(B\) are 100 J/mol/K and 200 J/mol/K, respectively.

- The heat of reaction is \(20\,000\) J/mol A reacted.

- The feed temperature is 400 K and the volumetric flow rate at the inlet is 1 L/s.

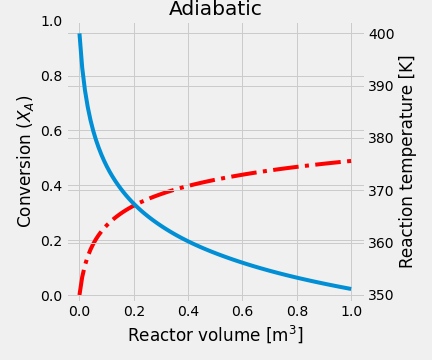

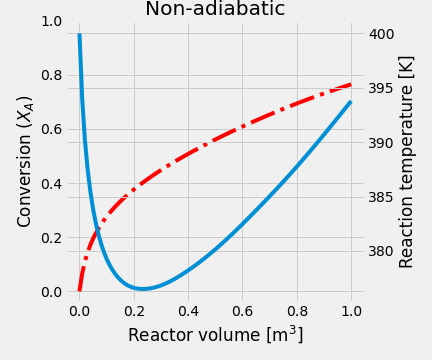

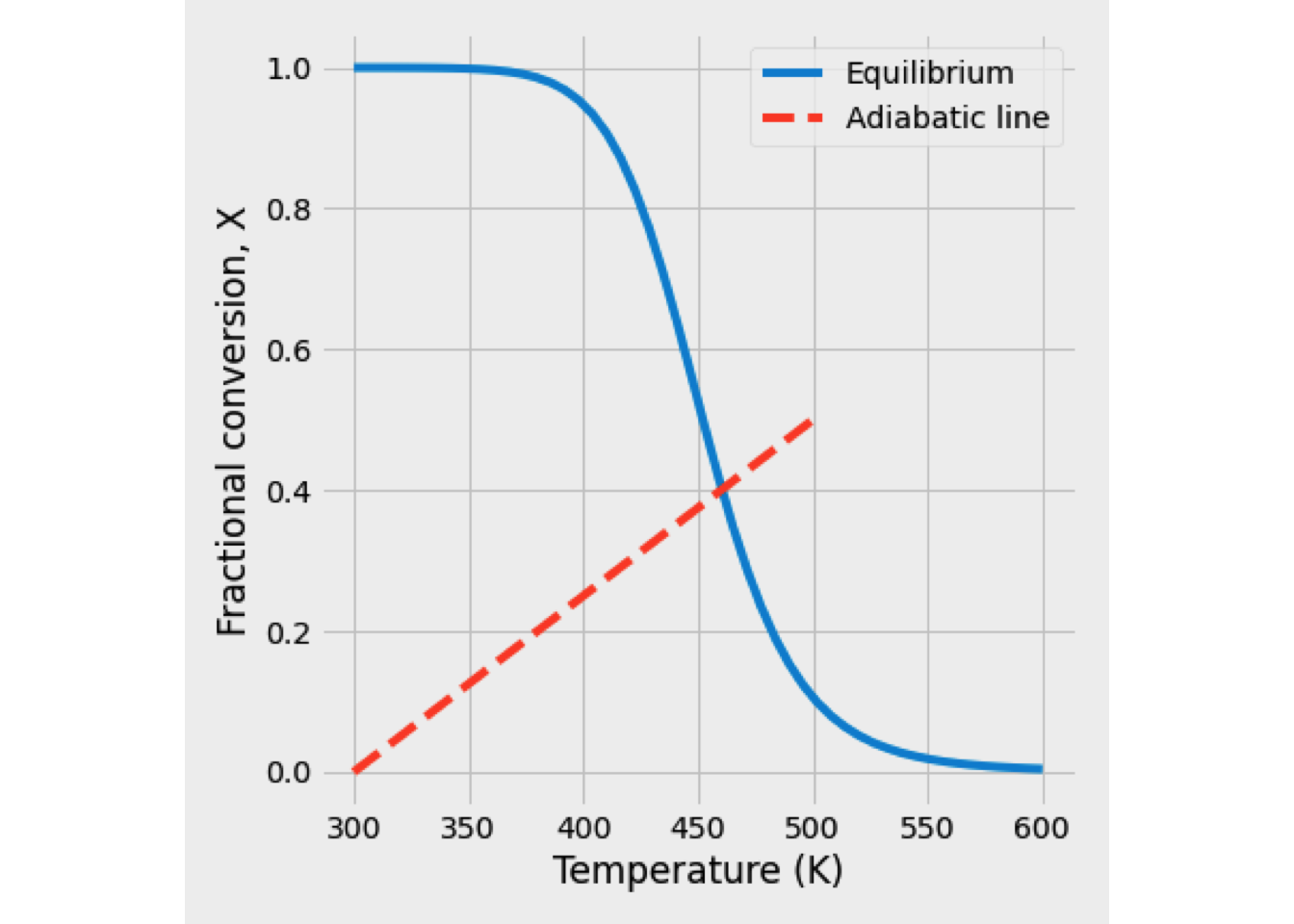

- If it is adiabatically in a PFR of 1 m\(^3\), what is conversion?

- If heating coil are employed, and we are given that \(U = 3\times 10^2\) W m\(^{-2}\), \(A = 2\)~m\(^2\) per m\(^3\) of PFR and \(T_J\) = 500 K, what is the conversion?

Solution. The solution of this problem is available in this link

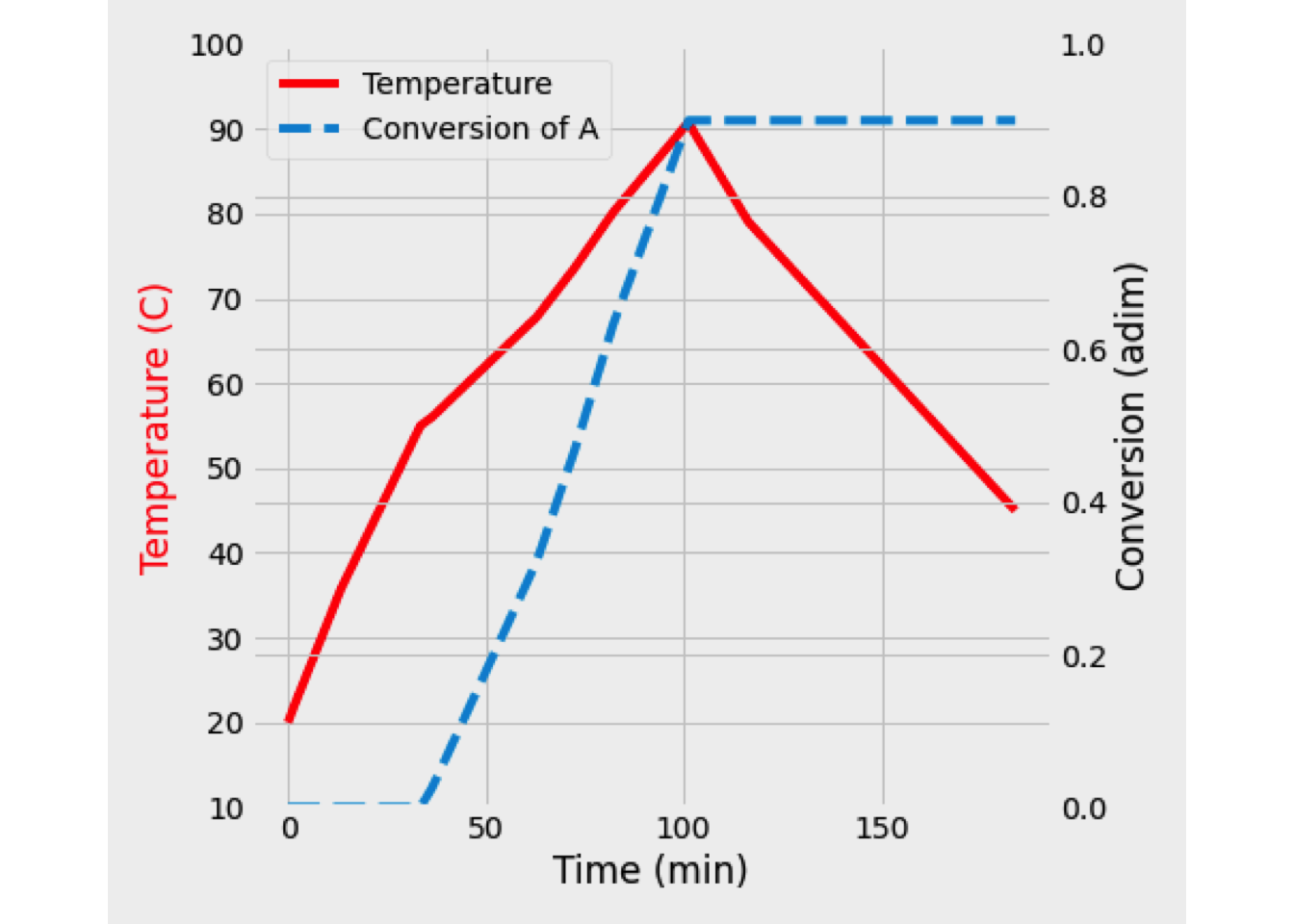

Since it is a liquid-phase reaction, no significant change in density is assumed.

- Under adiabatic conditions, we have to solve two equations: \[\begin{gather*} \frac{dX_A}{dV} = - \frac{r_A}{F_{A0}} \\ \cfrac{dT}{dV} = \cfrac{\Delta H_R \,r_A}{F_A\,C_{P_A}+F_I\,C_{P_I}+F_B\,C_{P_B}} \end{gather*}\]

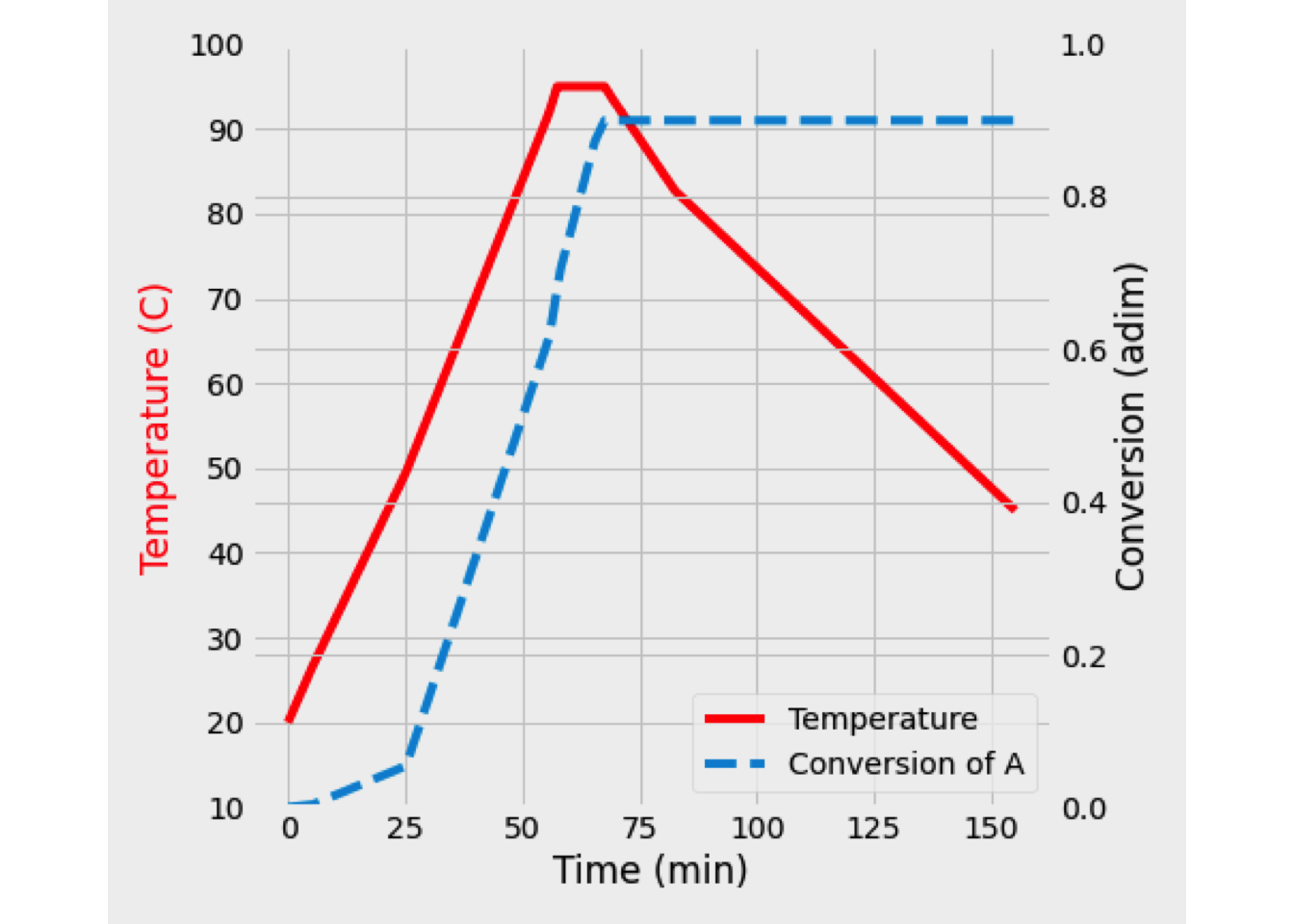

This system of equations was solved, and the reaction temperature was 351 K, while the conversion of A equals 48.89%.

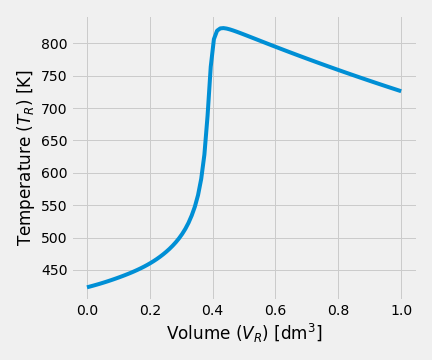

In the next figure is shown the temperature and conversion profile obtained. In the beginning, the temperature is high, as well as the concentration of A. Later both temperature and conversion drop drastically, so the reaction rate is slowing down a lot.

- When the heating coil is used, the heat balance must change to include the quantity of heat-related to the heat exchanger. \[\begin{equation*} \frac{dT}{dV} = \frac{U\left(\frac{A}{V_\text{max}}\right)\left(T_J-T\right) + \Delta H_R \,r_A}{F_A\,C_{P_A}+F_I\,C_{P_I}+F_B\,C_{P_B}} \end{equation*}\]

In this case, the output is at 394 K, and the conversion is 76.53%. Temperature and conversion profiles are shown in figure Y

| Without heat exchanger | With heat exchanger |

|---|---|

|

|

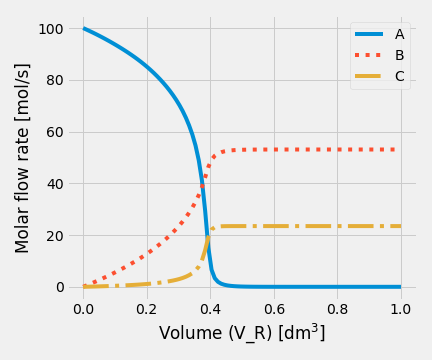

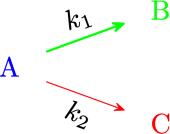

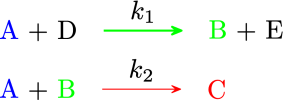

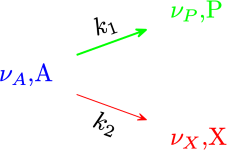

Exercise 2.6 (Parallel Reactions in a PFR with Heat Effects) Consider next set of reactions which occurs in gas-phase \[\begin{align*} &A \xrightarrow[]{k_1} B\\ &2A \xrightarrow[]{k_2} C \end{align*}\] with \(r_{1} = k_{1}\,C_A\) and \(r_{2} = k_{2}\,C_A^2\) Pure \(A\) is fed at a rate of 100 mol/s, a temperature of 150 \(^\circ\)C and a concentration of 0.1 mol/dm\(^3\). Determine the temperature and flow rate profiles down the reactor.

Solution. This problem was solved from following set of equations:

Kinetics equations: \[\begin{align*} r_1 &= k_1\,C_A\\ r_2 &= k_2\,C_A^2 \end{align*}\] Mole balances: \[\begin{align*} \frac{dF_A}{dV} &= r_A = - r_1 - 2\,r_2\\ \frac{dF_B}{dV} &= r_B = r_1 \\ \frac{dF_C}{dV} &= r_C = r_2 \end{align*}\] Energy balance: \[\begin{equation*} \frac{dT}{dV} = \frac{Ua\left(T_J - T\right) + r_{A1}\,\Delta H_{R1} + r_{A2}\,\Delta H_{R2}}{F_A\,C_{P_A} + F_B\,C_{P_B} + F_C\,C_{P_C} } \end{equation*}\]

| Temperature profile | Molar flowrates |

|---|---|

|

|

2.3.3 Recycle PFR

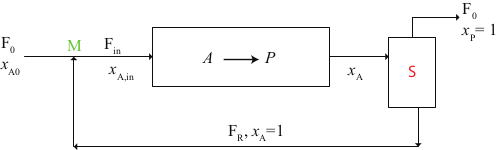

A recycling reactor is an ideal tubular reactor that part of the effluent stream back to the reactor inlet. As shown in Figure 2.19. Recycle can control the temperature in the reactor and adjust the product distribution if more than one reaction is taking place.

Figure 2.19: Recycle PFR

Based on the flowsheet in Fig. 2.19, the feed to the process is denoted by the subscript ‘’o’’ with is mixed at the point M with the recycle stream, denoted by a subscript ‘’R’‘. The mixed stream, which is denoted by a subscript’‘in’’, is then fed to the reactor.

At point S, the outlet stream from the reactor, which is denoted by a subscript ‘’out’‘, is split into recycle stream and the final stream leaving the process (denoted by a subscript’‘f’’). The recycle ratio, R, as defined as \[\begin{equation*} R = \frac{\upsilon_R}{\upsilon_f} = \frac{F_{\text{tot},R}}{F_{\text{tot},f}} = \frac{F_{A,R}}{F_{A,f}} \end{equation*}\] where \(\upsilon\) and \(F\) are the volumetric and molar flow, respectively.

If the fresh feed \(F_o\) contains a molar fraction \(x_{Ao}\), and the reactor product a molar fraction \(x_{A}\) of the specie \(A\), then the molar balance for \(A\) at point \(M\) is \[\begin{equation*} F_{A,in} = F_{A,0} + F_{A,R} = F_{A,0} + R \, F_{A,f} \end{equation*}\]

On the other hand, the \(A\) balance at point S is \[\begin{equation*} F_{A,out} = F_{A,f} + F_{A,R} = F_{A,f} + R \, F_{A,f} = \left(1 + R \right) F_{A,f} \Rightarrow F_{A,f} = \frac{F_{A,out}}{1 + R} \end{equation*}\]

Combining those last two equations, the desired expression for the initial value of the molar flow rate of A will be: \[\begin{equation*} F_{A,in} = F_{A,0} + R\,\frac{F_{A,out}}{1 + R} \end{equation*}\]

The material balance may obtain the volume of the recycled PFR for the reactant \(A\) into the reactor, which is \[\begin{equation} \frac{V }{F_\text{in}} = - \int_{X_{A,\text{in}} }^{X_A} {\frac{dX_A }{r_A }} \tag{2.64} \end{equation}\]

However, there are at least two ways to define the conversion of a system like this. One is the per-pass conversion given in eq. (2.66) and the other is the overall conversion given in equation (2.66).

\[\begin{gather} X_{A,pass} = \frac{F_{A,in} - F_{A,out}}{F_{A,in}} \tag{2.65} \\ X_{A,overall} = \frac{F_{A,0} - F_{A,f}}{F_{A,0}} \tag{2.66} \end{gather}\]

It is essential to consider that the reactor’s volumetric flow rate is greater than the volumetric flow rate entering the process when the rate expression contains concentrations.

The definition of concentration (eq. (2.67)) is used as usual. For a gas-phase system, the volumetric flow rate, in the denominator, is written using an appropriate equation of state. \[\begin{equation} C_i = \frac{F_i}{\upsilon} \tag{2.67} \end{equation}\]

On the other hand, if the fluid is a liquid of constant density, the reactor’s volumetric flow rate must be used according to Eq. (2.68) \[\begin{equation} C_i =\frac{F_i}{\upsilon_{in}} = \frac{F_i}{\upsilon_{0}\left(1 + R\right)} \tag{2.68} \end{equation}\]

When the recycled PFR operates at non-isothermal temperature, the initial condition for the temperature is found at point M while noting that \(T_{out} = T_R = T_f\). Assuming that no phase change occurs in any of the streams, the heat balance would be: \[\begin{equation} \sum_i \left(F_{i,0} \int_{T_0}^{T_{in}} C_{P,i} dT \right) + \sum_i \left(F_{i,R} \int_{T_R}^{T_{in}} C_{P,i} dT \right) = 0 \tag{2.69} \end{equation}\] Therefore, the temperature of the stream ‘’in’’ \[\begin{equation} T_{in} = T_0\,\frac{\sum_i \left(F_{i,0} C_{P,i} \right) + T_R\, \sum_i \left(F_{i,R} C_{P,i}\right)}{\sum_i \left(F_{i,in} C_{P,i} \right) } (\#eq:ectemp_in) \end{equation}\]

In summary, the performance of a non-isothermal recycle PFR must be calculate \[\begin{align} &\frac{dF_i}{dz} = \frac{\pi D^2}{4}\sum \nu_{i,j} r_j \\ & \pi D U \left(T_e - T\right) = \left(\sum F_i C_{P,i}\right)\frac{dT}{dz} + \frac{\pi D^2}{4} \sum r_j \Delta H_j \\ & F_i \left(z =0\right) = F_{i,in} = F_{i,0} + \frac{R}{1+R} F_{i,out} \\ & T \left(z=0\right) = T_{in} \end{align}\]

This EDO system must be solved using successive substitution because the flow rate and temperature of stream ``in’’ usually are not provided. To calculate the initial values of these variables is necessary to know the molar flow rate and temperature of the stream ‘’out’’. However, \(F_{i,in}\) and \(T_{in}\) are needed to integrate the design equation and calculate \(F_{i,out}\) and \(T_{out}\).

The problem could be solved by calculating an initial guess for the conditions of stream ``in’’ assuming that there is no recycle stream. The previous calculation provides an educated-guess for the composition and temperature of the recycle stream ‘’R’’. The rest of the calculations are performed using these values as initial conditions.

Under isothermal operation and assuming that \(F_0 = F_f\), and noting that \(x_{A,R} = x_{A,out} = x_{A,f}\), the problem is much easier to solve. A balance for A at point M. \[\begin{equation*} F_0\,x_{A,0} + F_R\,x_{A,R} = F_\text{in}\,x_{A,in} \end{equation*}\] Now, a balance on the reactor \[\begin{equation*} F_\text{in} = F_{out} = F_f \left(1 + R\right) \equiv F_0 \left(1 + R\right) \end{equation*}\] Therefore \[\begin{align*} x_{A,\text{in}} &= \frac{F_0\,x_{A,0} + F_R \,x_{A,f}}{F_\text{in}} \\ & = \frac{F_0\,x_{A,0} + F_0\,R\,x_{A,f}}{F_{out}} = \frac{F_0\left( x_{A,0} + R\,x_{A,f}\right)}{F_0 \left(1 + R\right) } \end{align*}\] where \(x_{A,k}\) referred to molar fraction of A in the stream \(k\)

Then, the total reactor feed contains a molar fraction \(x_{A,\text{in}}\), given by \[\begin{equation} x_{A,\text{in}} = \frac{x_{Ao} + R\,x_{A}}{1+R} \tag{2.70} \end{equation}\]